ຄວາມໜ້າເຊື່ອຖືທີ່ດີຂຶ້ນຜ່ານການປ້ອງກັນສິ່ງແວດລ້ອມທີ່ແຂງແຮງ

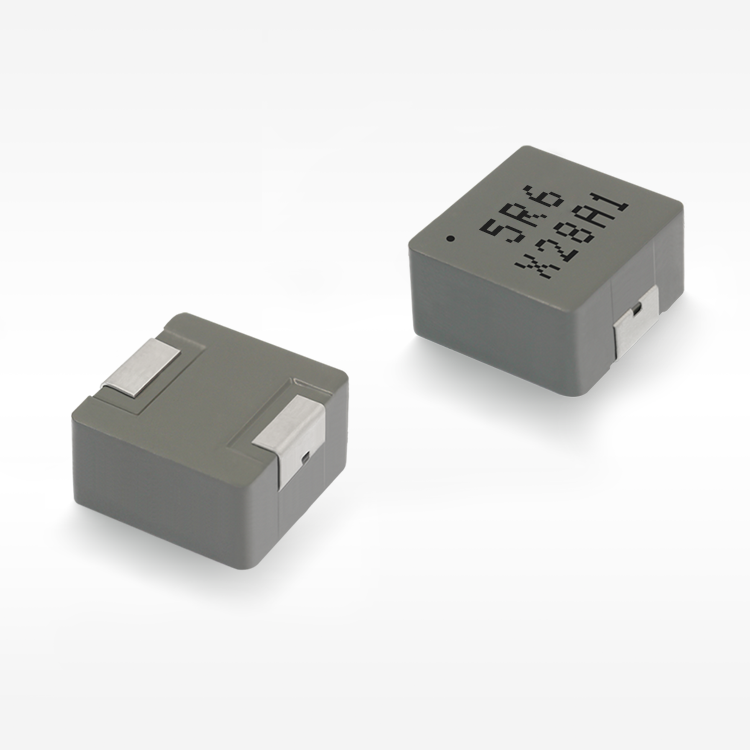

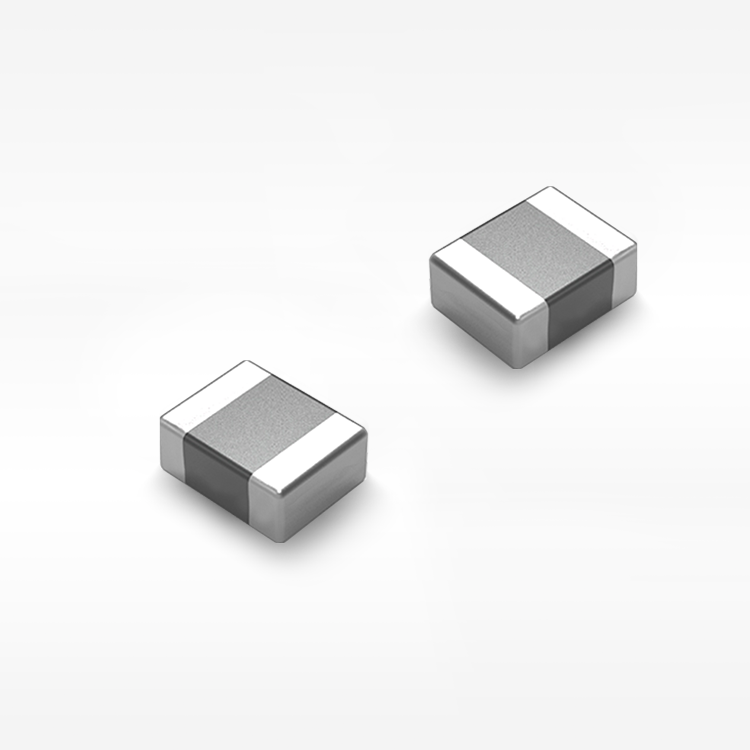

ຂດລວດພະລັງງານທີ່ຖືກຂຶ້ນຮູບມາໃຫ້ການປ້ອງກັນສິ່ງແວດລ້ອມທີ່ດີເລີດຜ່ານເຕັກໂນໂລຊີການຫຸ້ມຫໍ່ຂັ້ນສູງ ທີ່ປ້ອງກັນສ່ວນປະກອບສຳຄັນຈາກສະພາບການໃຊ້ງານທີ່ຮຸນແຮງ ໃນຂະນະທີ່ຮັກສາການປະຕິບັດງານດ້ານໄຟຟ້າໃຫ້ຢູ່ໃນລະດັບທີ່ດີທີ່ສຸດ. ລະບົບການປ້ອງກັນທີ່ຄົບຖ້ວນນີ້ ຈັດການກັບຄວາມທ້າທາຍດ້ານສິ່ງແວດລ້ອມຫຼາຍດ້ານ ລວມທັງການເຂົ້າຂອງຄວາມຊື້ນ, ການປ່ຽນແປງອຸນຫະພູມ, ຄວາມເຄັ່ງຕຶງທາງກົນຈັກ, ແລະ ການສຳຜັດກັບສານເຄມີ ທີ່ມັກຈະມີຜົນກະທົບຕໍ່ສ່ວນປະກອບໄຟຟ້າໃນການນຳໃຊ້ຈິງ. ການສ້າງຂຶ້ນຮູບແບບນີ້ສ້າງເປັນຊັ້ນຜນຶກອາກາດອ້ອມຮອບເຄື່ອງແມ່ເຫຼັກ ແລະ ລວດ, ປ້ອງກັນການດູດຊຶມຂອງຄວາມຊື້ນ ທີ່ສາມາດເຮັດໃຫ້ຄຸນສົມບັດດ້ານໄຟຟ້າເສື່ອມ ແລະ ເຮັດໃຫ້ການປະຕິບັດງານຜັນປ່ຽນໄປຕາມເວລາ. ການປ້ອງກັນຄວາມຊື້ນນີ້ ມີຄວາມສຳຄັນໂດຍສະເພາະໃນການນຳໃຊ້ດ້ານລົດຍົນ, ອຸປະກອນນອກອາຄານ, ແລະ ລະບົບອຸດສາຫະກຳ ບ່ອນທີ່ການປ່ຽນແປງຄວາມຊື້ນ ແລະ ການກ້ອນຕົວມີຢູ່ຕະຫຼອດເວລາ. ຄຸນສົມບັດການຕ້ານທານສານເຄມີຂອງວັດສະດຸທີ່ຖືກຂຶ້ນຮູບ ຊ່ວຍປ້ອງກັນການສຳຜັດກັບສານລ້າງ, ສ່ວນເຫຼືອຂອງແຟັກ, ແລະ ມົນລະພິດສິ່ງແວດລ້ອມ ທີ່ສາມາດເຮັດໃຫ້ຄວາມສົມບູນຂອງສ່ວນປະກອບເສື່ອມໂດຍ. ການຕ້ານທານຕໍ່ການປ່ຽນແປງອຸນຫະພູມ ຮັບປະກັນການດຳເນີນງານທີ່ເຂັ້ມງວດຜ່ານວົງຈອນຄວາມເຄັ່ງຕຶງທາງຄວາມຮ້ອນ ທີ່ເກີດຂຶ້ນເລື້ອຍໆໃນສະພາບແວດລ້ອມດ້ານລົດຍົນ ແລະ ອຸດສາຫະກຳ, ບ່ອນທີ່ສ່ວນປະກອບຈະປະສົບກັບການປ່ຽນແປງອຸນຫະພູມຢ່າງຫຼວງຫຼາຍໃນຂະນະທີ່ດຳເນີນງານປົກກະຕິ. ການປ້ອງກັນທາງກົນຈັກທີ່ແຂງແຮງ ສາມາດຕ້ານທານຕໍ່ການສັ່ນສະເທືອນ ແລະ ການຊອກທີ່ເກີນມາດຕະຖານອຸດສາຫະກຳ, ເຮັດໃຫ້ຂດລວດພະລັງງານທີ່ຖືກຂຶ້ນຮູບເໝາະສຳລັບການນຳໃຊ້ໃນການທະຫານ, ອາວະກາດ, ແລະ ອຸດສາຫະກຳໜັກ ບ່ອນທີ່ຄວາມເຄັ່ງຕຶງທາງກົນຈັກເປັນບັນຫາດ້ານຄວາມນິຍົມທີ່ສຳຄັນ. ລູກຄ້າໄດ້ຮັບປະໂຫຍດຈາກອາຍຸການໃຊ້ງານທີ່ຍາວຂຶ້ນ ແລະ ຄວາມຕ້ອງການການບຳລຸງຮັກສາທີ່ຫຼຸດລົງ, ເນື່ອງຈາກການປ້ອງກັນທີ່ດີຂຶ້ນຊ່ວຍຫຼຸດຜ່ອນການເສື່ອມສະພາບ ແລະ ອັດຕາການຂັດຂ້ອງຂອງສ່ວນປະກອບ. ການປ້ອງກັນດ້ານສິ່ງແວດລ້ອມນີ້ຍັງຊ່ວຍງ່າຍຂຶ້ນໃນການອອກແບບລະດັບລະບົບ ໂດຍການລຶບລ້າງຄວາມຈຳເປັນໃນມາດຕະການປ້ອງກັນເພີ່ມເຕີມ ເຊັ່ນ: ການຄຸມຊັ້ນປ້ອງກັນ ຫຼື ກ່ອງປ້ອງກັນສິ່ງແວດລ້ອມ. ໂປຣໂທຄອນການທົດສອບຄຸນນະພາບ ຢັ້ງຢືນຄວາມສາມາດໃນການປ້ອງກັນຜ່ານການທົດສອບອາຍຸການໃຊ້ງານທີ່ເຮັງ, ການປ່ຽນແປງອຸນຫະພູມ, ການສຳຜັດກັບຄວາມຊື້ນ, ແລະ ການທົດສອບຄວາມເຄັ່ງຕຶງທາງກົນຈັກ ທີ່ຈຳລອງການດຳເນີນງານໃນສະພາບແວດລ້ອມຈິງເປັນສິບປີ. ການຢັ້ງຢືນຄົບຖ້ວນນີ້ ໃຫ້ຄວາມໝັ້ນໃຈແກ່ລູກຄ້າໃນຄວາມນິຍົມ ແລະ ຄວາມສອດຄ່ອງຂອງການປະຕິບັດງານໃນໄລຍະຍາວ. ຄຸນສົມບັດການປ້ອງກັນທີ່ດີຂຶ້ນນີ້ຍັງຊ່ວຍໃຫ້ການປະຕິບັດຕາມມາດຕະຖານອຸດສາຫະກຳ ລວມທັງຂໍ້ກຳນົດການຮັບຮອງດ້ານລົດຍົນ, ຂໍ້ກຳນົດທາງການທະຫານ, ແລະ ມາດຕະຖານຄວາມນິຍົມດ້ານການສື່ສານ, ຊ່ວຍຫຼຸດຜ່ອນຄ່າໃຊ້ຈ່າຍໃນການຮັບຮອງ ແລະ ເວລາກ່ອນນຳອອກສູ່ຕະຫຼາດສຳລັບຜະລິດຕະພັນຂອງລູກຄ້າ.