ferrite shielded power inductor

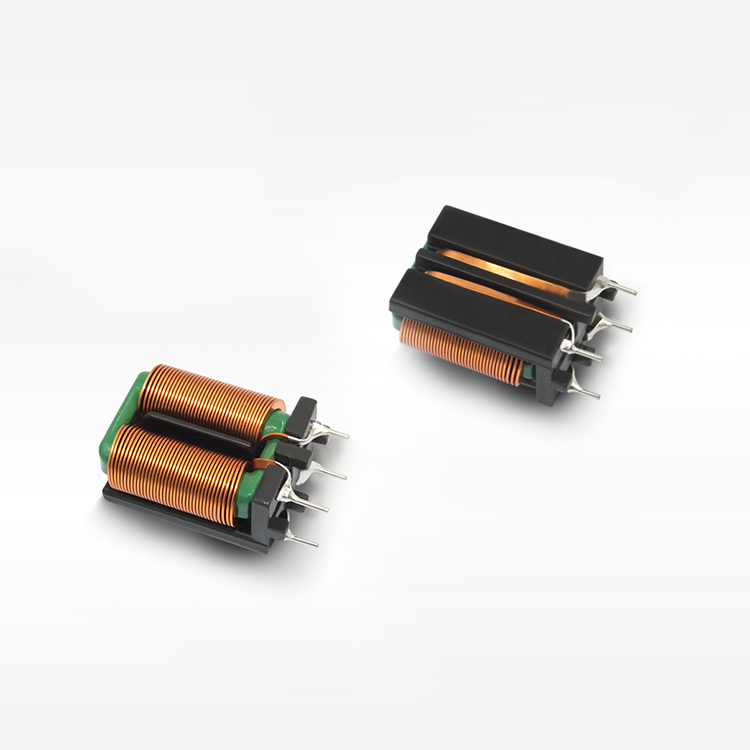

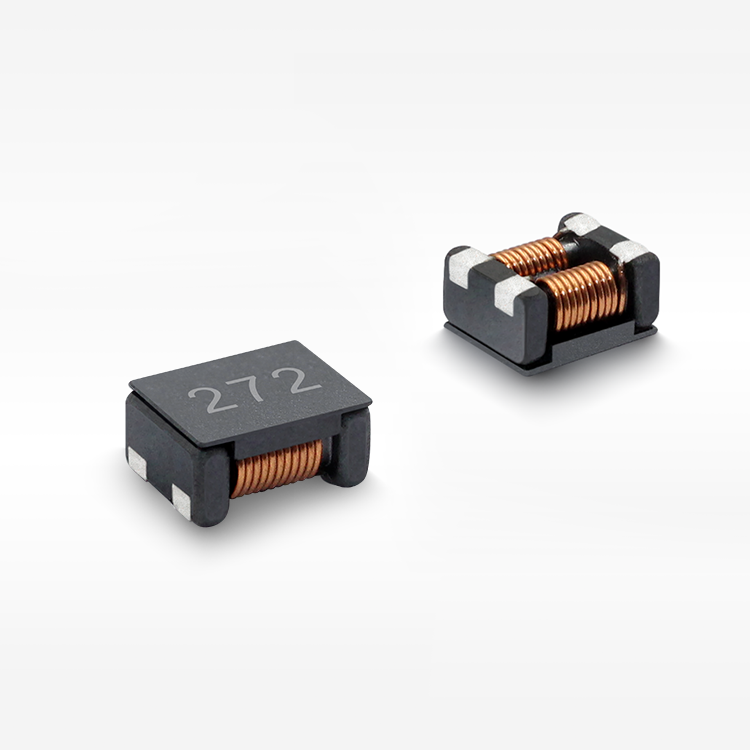

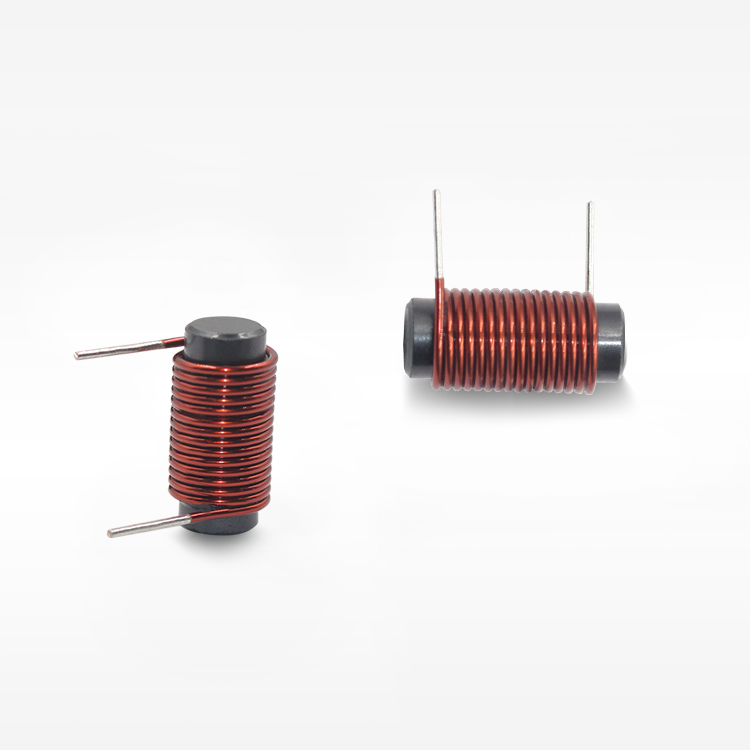

The ferrite shielded power inductor represents a critical component in modern electronic systems, designed to manage electromagnetic interference while delivering exceptional power handling capabilities. This sophisticated electronic component combines ferrite core technology with advanced shielding mechanisms to create a robust solution for various power management applications. The ferrite shielded power inductor operates by storing energy in its magnetic field when current flows through its windings, effectively smoothing current fluctuations and reducing electrical noise in circuits. The ferrite core material provides high magnetic permeability, enabling efficient energy storage while maintaining compact dimensions. The integrated shielding design minimizes electromagnetic interference between adjacent components, ensuring optimal circuit performance in densely packed electronic assemblies. These inductors feature carefully engineered wire windings wrapped around ferrite cores, with specialized shielding materials that contain magnetic flux within the component boundaries. The technological architecture incorporates saturation-resistant ferrite materials that maintain stable inductance values across varying current levels, temperature ranges, and operating frequencies. Modern ferrite shielded power inductor designs utilize advanced manufacturing processes that ensure consistent electrical characteristics and mechanical reliability. The shielding technology typically employs magnetic materials or metallic enclosures that redirect electromagnetic fields, preventing interference with nearby sensitive components. Applications for ferrite shielded power inductor solutions span across switching power supplies, DC-DC converters, LED drivers, automotive electronics, telecommunications equipment, and consumer electronics. In switching power supplies, these inductors smooth output currents and reduce ripple voltages, improving overall system efficiency. Telecommunications infrastructure relies on ferrite shielded power inductor components for signal conditioning and power regulation in base stations and networking equipment. Automotive applications utilize these inductors in electric vehicle charging systems, engine control units, and advanced driver assistance systems where electromagnetic compatibility requirements are stringent.