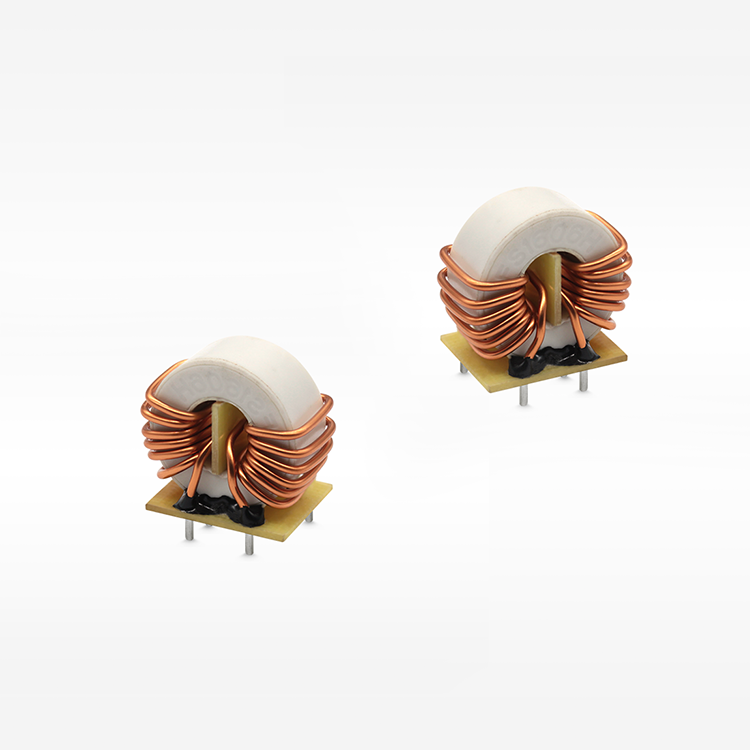

Superior Electromagnetic Interference Suppression

The magnetic shielded power inductor excels in electromagnetic interference suppression through its innovative multi-layer shielding architecture that provides comprehensive protection against unwanted electromagnetic emissions and external interference. This advanced shielding system incorporates specialized ferrite materials and conductive barriers that create multiple interference suppression mechanisms working in synergy to maintain signal integrity and system performance. The primary shielding layer utilizes high-permeability ferrite materials that effectively contain magnetic fields generated during normal inductor operation, preventing these fields from coupling with adjacent circuit traces and components that could experience performance degradation. Secondary shielding elements provide additional electromagnetic barrier protection, creating a comprehensive containment system that exceeds traditional inductor shielding capabilities. This multi-faceted approach ensures that sensitive analog circuits, radio frequency components, and digital signal processing elements remain isolated from electromagnetic disturbances that could compromise system functionality. The shielding effectiveness measurements demonstrate significant attenuation levels across broad frequency ranges, making the magnetic shielded power inductor suitable for applications operating in electromagnetically challenging environments such as automotive systems, industrial control equipment, and telecommunications infrastructure. Manufacturing precision ensures consistent shielding performance across production batches, providing predictable electromagnetic compatibility characteristics that simplify system-level electromagnetic compliance testing and certification processes. The integrated shielding design eliminates the need for external electromagnetic interference suppression components such as ferrite beads, additional shield cans, or electromagnetic gaskets that would otherwise increase system complexity and manufacturing costs. Engineers benefit from reduced electromagnetic compatibility design iterations and faster time-to-market schedules when incorporating magnetic shielded power inductors into their designs. The comprehensive electromagnetic protection extends component operational reliability by preventing electromagnetic stress conditions that could accelerate component aging or cause intermittent performance issues over extended operational periods.