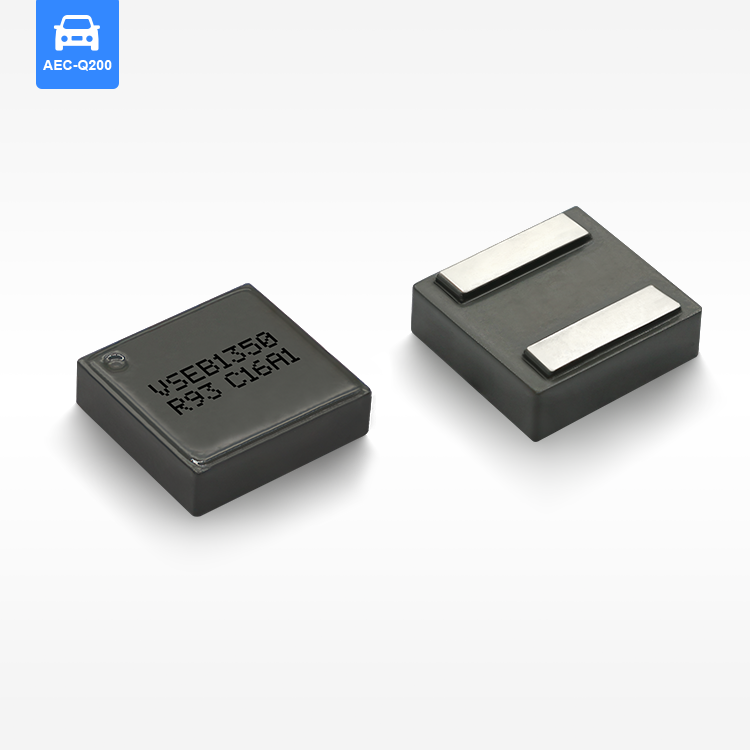

high efficiency shielded power inductor

A high efficiency shielded power inductor represents a critical electronic component designed to store and release energy in electrical circuits while maintaining exceptional performance standards. This sophisticated device combines magnetic shielding technology with optimized coil designs to deliver superior electromagnetic interference suppression and enhanced power handling capabilities. The primary function of a high efficiency shielded power inductor centers on energy storage through magnetic fields, current filtering, and voltage regulation in various electronic applications. The magnetic shielding feature distinguishes this component from traditional inductors by containing electromagnetic fields within the device structure, preventing interference with nearby components and circuits. Technological innovations in high efficiency shielded power inductors include advanced core materials such as ferrite and powdered iron, which maximize magnetic permeability while minimizing core losses. Modern manufacturing techniques employ precision winding methods and automated assembly processes to ensure consistent electrical characteristics and mechanical reliability. The shielding mechanism typically utilizes magnetic materials or conductive enclosures that redirect electromagnetic fields, creating a contained environment for optimal inductor performance. These components feature low DC resistance characteristics, high saturation current ratings, and excellent temperature stability across wide operating ranges. Applications for high efficiency shielded power inductors span numerous industries including automotive electronics, telecommunications equipment, computer motherboards, LED lighting systems, and renewable energy converters. In switching power supplies, these inductors serve as energy storage elements in buck, boost, and buck-boost converter topologies. Mobile device manufacturers integrate high efficiency shielded power inductors into battery management systems and power distribution networks to maintain stable voltage levels while minimizing electromagnetic emissions. The automotive sector relies on these components for engine control units, infotainment systems, and electric vehicle charging infrastructure. Industrial automation systems utilize high efficiency shielded power inductors in motor drives, frequency converters, and power factor correction circuits where electromagnetic compatibility requirements demand superior shielding performance.