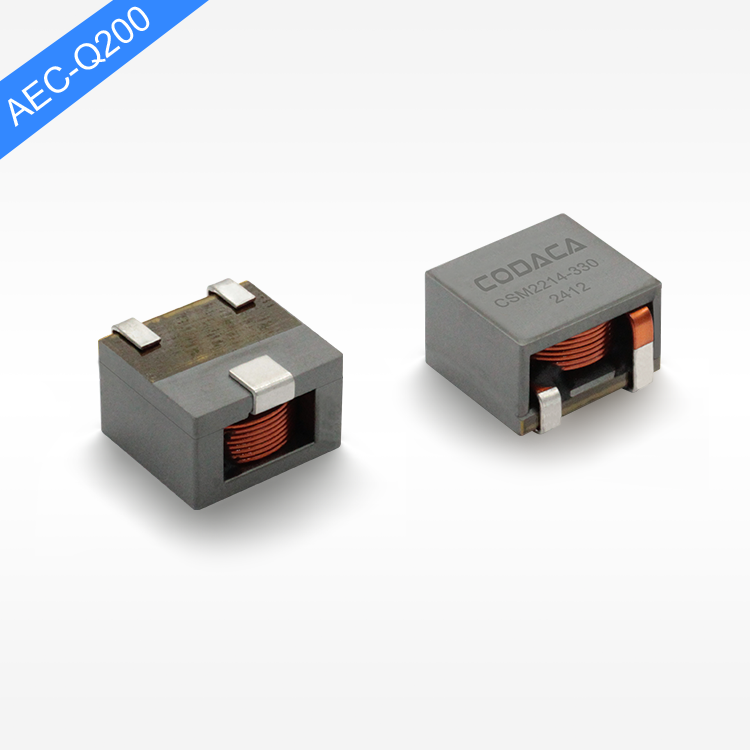

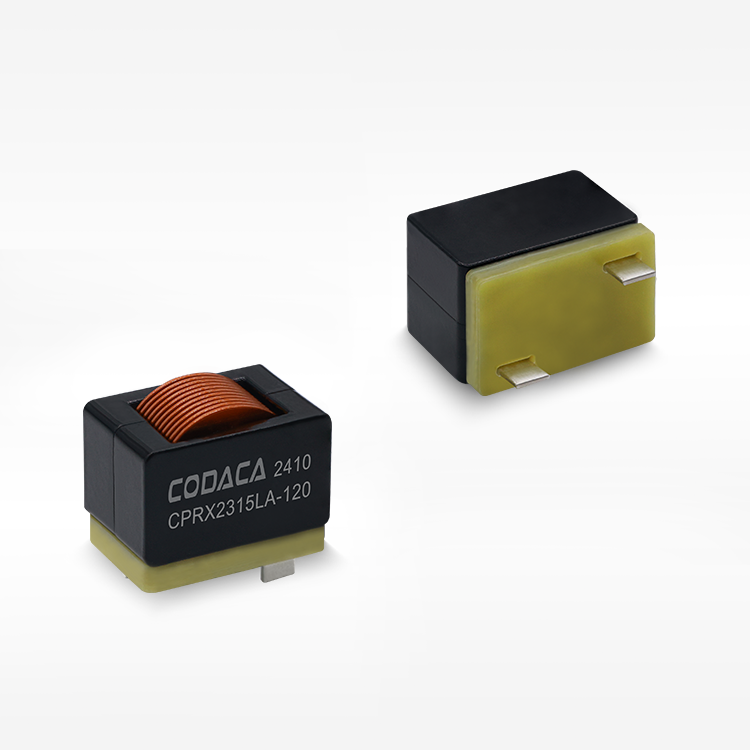

shielded power inductor factory

A shielded power inductor factory represents a specialized manufacturing facility dedicated to producing high-performance electromagnetic components essential for modern electronic systems. These sophisticated manufacturing plants focus on creating inductors with magnetic shielding that prevents electromagnetic interference while maintaining optimal power efficiency. The primary function of a shielded power inductor factory involves designing, engineering, and mass-producing inductors that feature enclosed magnetic cores, typically constructed from ferrite materials or powdered iron compounds. The shielded power inductor factory utilizes advanced winding techniques and precision assembly processes to ensure consistent electrical characteristics across all produced units. These facilities incorporate cutting-edge technology including automated coil winding machinery, computerized testing equipment, and cleanroom environments to maintain product quality standards. The technological features of a modern shielded power inductor factory include sophisticated magnetic field simulation software, precision measurement instruments for inductance values, and specialized coating applications for environmental protection. Quality control systems within the shielded power inductor factory employ rigorous testing protocols to verify electrical specifications, thermal performance, and mechanical durability. Applications for products manufactured in a shielded power inductor factory span numerous industries including automotive electronics, telecommunications infrastructure, computer power supplies, LED lighting systems, and renewable energy converters. The shielded power inductor factory serves critical roles in producing components for DC-DC converters, switching power supplies, and energy storage systems. Modern manufacturing processes within the shielded power inductor factory emphasize environmental sustainability through efficient material usage, waste reduction programs, and energy-efficient production methods. The facility typically maintains certifications including ISO quality standards, automotive industry specifications, and environmental compliance requirements to ensure global market acceptance of manufactured products.