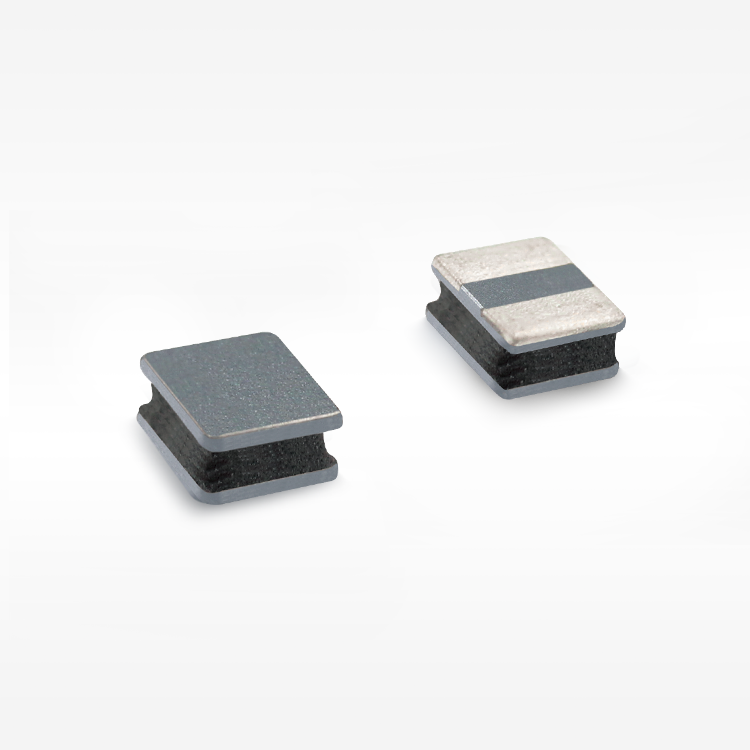

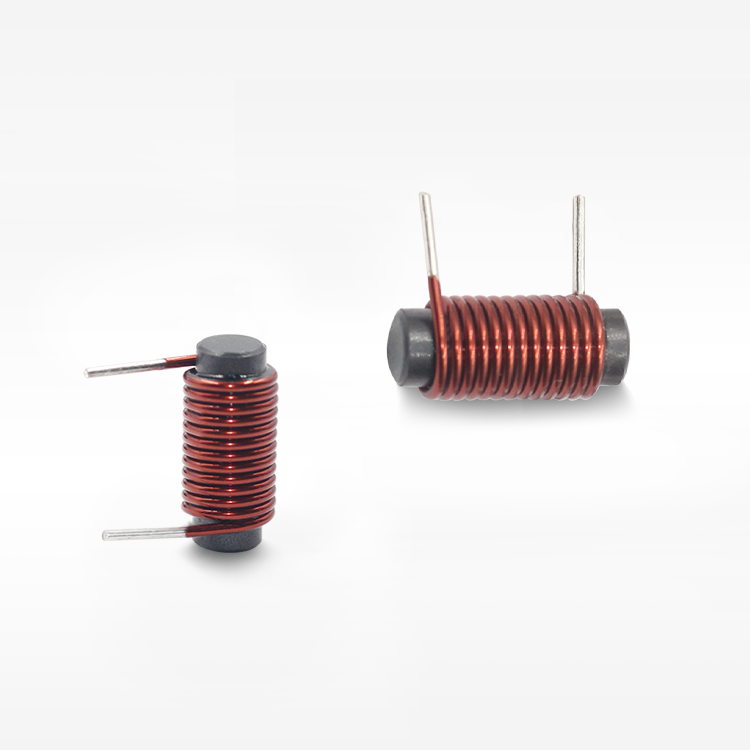

high saturation current shielded inductor

The high saturation current shielded inductor represents a sophisticated electronic component engineered to deliver exceptional performance in power management applications. This specialized inductor combines advanced magnetic core materials with precise winding techniques and integrated magnetic shielding to achieve superior electrical characteristics. The primary function of a high saturation current shielded inductor centers on energy storage and filtering within electronic circuits, particularly in switching power supplies, DC-DC converters, and voltage regulation modules. The component stores electrical energy in its magnetic field when current flows through its windings, then releases this energy as needed to maintain stable circuit operation. The shielding feature provides crucial electromagnetic interference suppression, preventing unwanted signal coupling between adjacent components and ensuring clean power delivery. Technological features include ferrite or powdered iron cores optimized for high magnetic permeability and saturation resistance. The core geometry and material composition allow these inductors to handle significantly higher current levels before magnetic saturation occurs compared to standard inductors. Advanced winding configurations using copper wire or specialized conductive materials minimize resistive losses while maximizing current-carrying capacity. The integrated shield, typically constructed from ferrite material or metal housing, creates a closed magnetic path that contains the magnetic field and reduces external interference. Manufacturing processes involve precision core assembly, controlled winding tension, and automated shield integration to ensure consistent electrical parameters. Applications span automotive electronics, telecommunications equipment, computer power supplies, LED drivers, solar inverters, and industrial motor controls. These inductors excel in high-power density designs where space constraints demand compact components capable of handling substantial current loads. The combination of high saturation current capability and effective shielding makes these components ideal for noise-sensitive applications requiring both power efficiency and electromagnetic compatibility compliance.