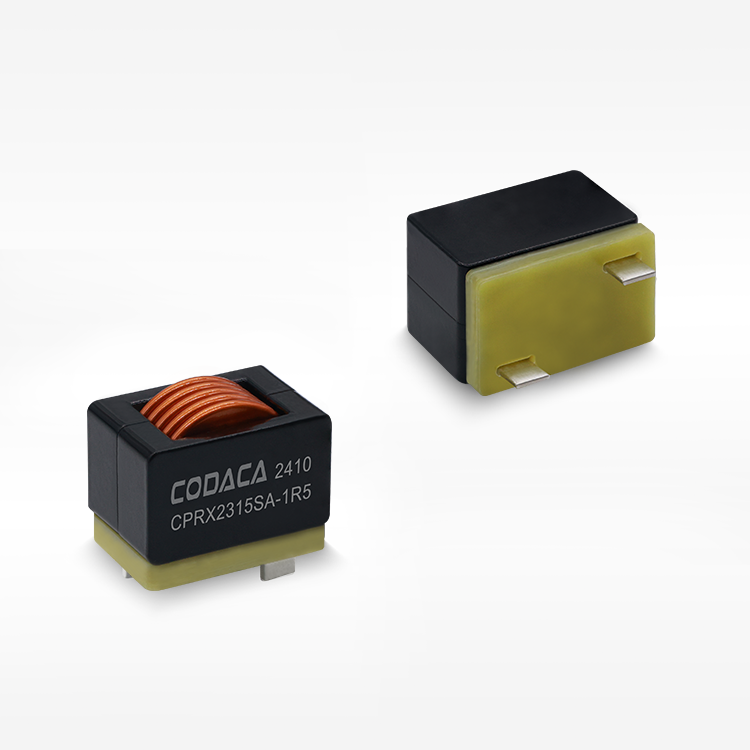

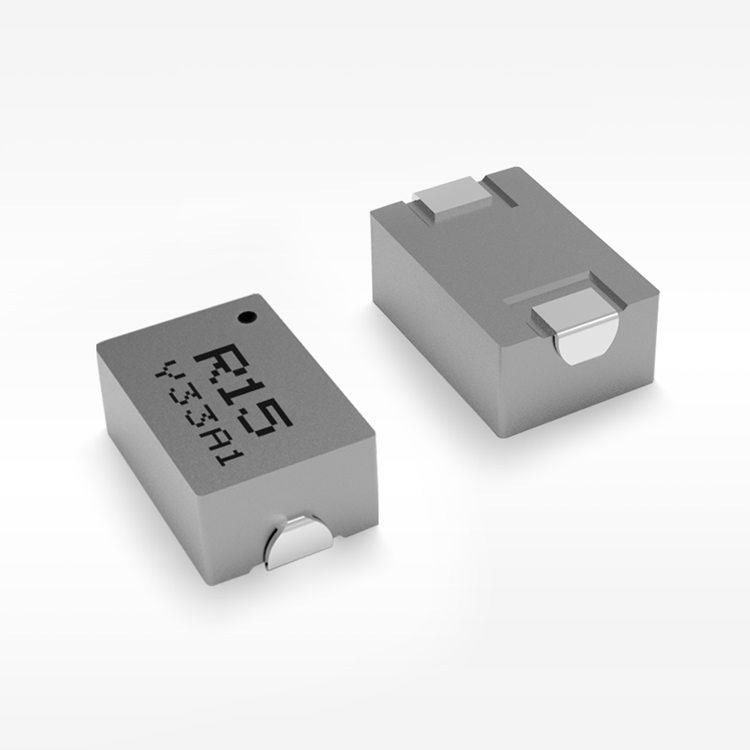

molded shielded power inductor

A molded shielded power inductor represents a critical electronic component designed to store energy in magnetic fields while managing electromagnetic interference in power supply circuits. These inductors feature a magnetic core encased in a molded housing with integrated shielding properties that prevent electromagnetic radiation from affecting nearby components. The primary function involves filtering alternating current signals, smoothing voltage ripples, and providing impedance control in switching power supplies, DC-DC converters, and various power management applications. The molded shielded power inductor incorporates advanced ferrite core materials that deliver high saturation current ratings while maintaining stable inductance values across wide temperature ranges. The shielding mechanism utilizes magnetic materials or conductive enclosures that contain magnetic flux within the component, significantly reducing electromagnetic interference emissions. This design approach ensures reliable operation in densely packed electronic systems where space constraints demand compact solutions without compromising performance. Manufacturing processes involve precision winding techniques that create uniform magnetic fields, followed by molded encapsulation using thermally stable polymers that protect against environmental factors including moisture, vibration, and temperature fluctuations. The technological features include low DC resistance characteristics that minimize power losses, excellent thermal management properties that enable high current handling capabilities, and superior frequency response that maintains performance across broad operating ranges. Applications span automotive electronics, telecommunications infrastructure, consumer electronics, industrial automation systems, renewable energy converters, and medical devices where power efficiency and electromagnetic compatibility requirements are paramount. These inductors prove essential in voltage regulator modules, point-of-load converters, battery management systems, LED drivers, and motor control circuits where precise current regulation and noise suppression capabilities determine overall system reliability and performance metrics.