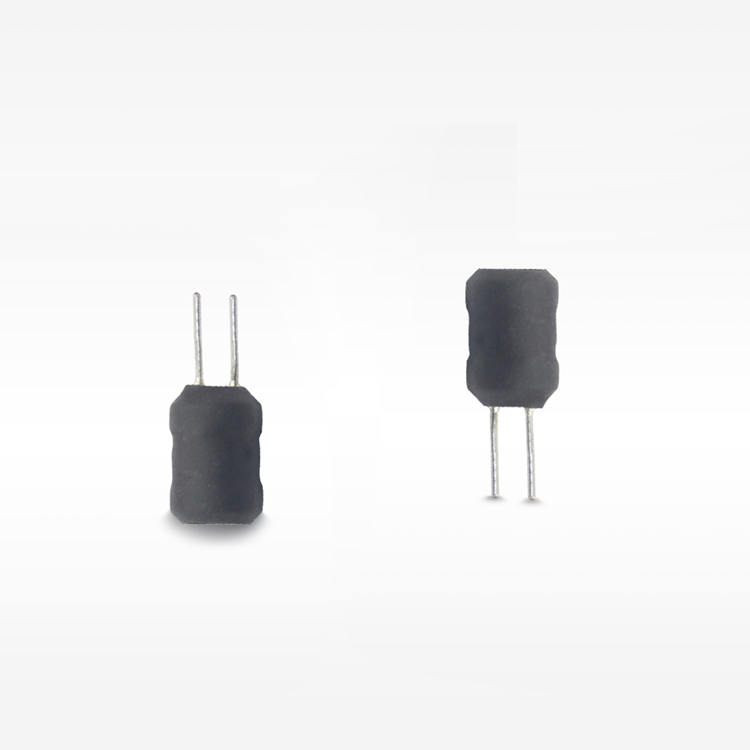

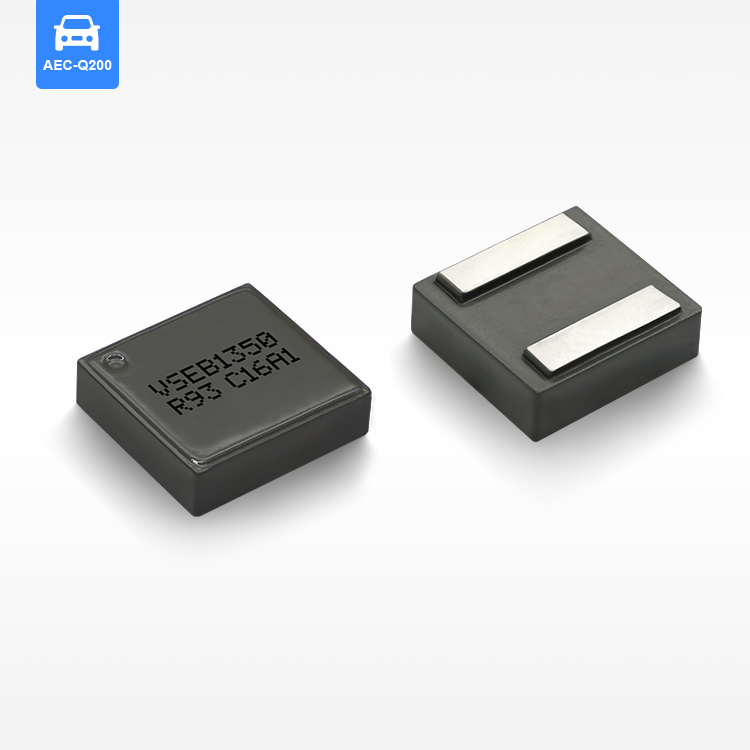

low loss shielded power inductor

The low loss shielded power inductor represents a critical component in modern electronic circuit design, engineered specifically to manage electrical energy storage and transfer while minimizing power dissipation. This sophisticated electronic component combines magnetic field containment with optimized energy efficiency, making it essential for applications requiring precise power management and electromagnetic interference control. The primary function of a low loss shielded power inductor centers on storing magnetic energy when current flows through its windings, then releasing this energy back into the circuit as needed. This fundamental operation enables voltage regulation, current smoothing, and energy conversion processes that are vital in switching power supplies, DC-DC converters, and various power management systems. The shielding technology incorporated into these inductors utilizes magnetic materials or metallic enclosures that contain the magnetic field generated by the current-carrying conductor. This containment prevents electromagnetic interference from affecting nearby components while simultaneously protecting the inductor from external magnetic influences that could compromise its performance. The technological features of low loss shielded power inductors include carefully selected core materials such as ferrite, powdered iron, or specialized alloys that exhibit minimal hysteresis losses and eddy current losses. These materials are engineered to operate efficiently across wide frequency ranges while maintaining stable inductance values under varying temperature and current conditions. Advanced winding techniques using high-quality copper wire with optimized gauge selection further reduce resistive losses, contributing to the overall low-loss characteristics. Manufacturing processes incorporate precision molding and assembly methods that ensure consistent performance parameters and reliable operation over extended periods. Applications for low loss shielded power inductors span numerous industries and electronic devices, including automotive electronics, telecommunications equipment, consumer electronics, industrial automation systems, and renewable energy converters. In automotive applications, these components support electric vehicle charging systems, engine control units, and advanced driver assistance systems. Telecommunications infrastructure relies on them for base station power supplies, signal processing equipment, and network switching systems. Consumer electronics utilize these inductors in smartphone chargers, laptop power adapters, LED lighting drivers, and audio amplification circuits.