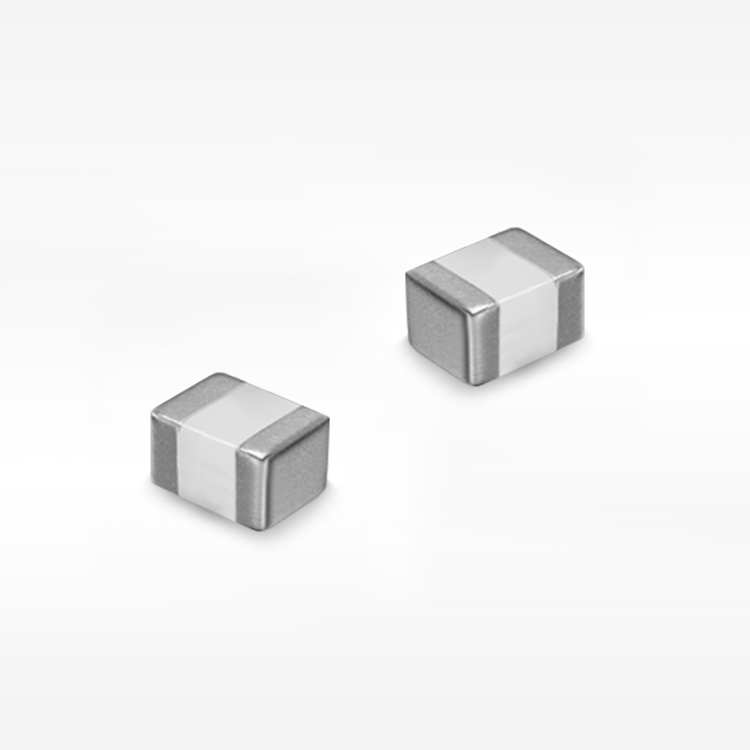

smd high current power inductor

The smd high current power inductor represents a cornerstone component in modern electronic design, engineered to handle substantial electrical currents while maintaining compact surface mount dimensions. These specialized inductors store energy in magnetic fields and regulate current flow in power conversion circuits, making them essential for applications requiring efficient power management. The smd high current power inductor distinguishes itself through its ability to process high amperage loads without compromising performance or reliability. These components feature ferrite or powdered iron cores wrapped with thick copper wire, enabling them to handle currents ranging from several amperes to hundreds of amperes depending on the specific model. The surface mount design eliminates the need for through-hole mounting, allowing for automated assembly processes and reduced board space requirements. Advanced manufacturing techniques ensure consistent inductance values and minimal resistance, contributing to overall system efficiency. The smd high current power inductor incorporates sophisticated thermal management properties, dissipating heat effectively during high-current operation. Modern variants utilize specialized core materials that maintain stable inductance across wide temperature ranges while minimizing core losses. The compact footprint makes these inductors ideal for space-constrained applications without sacrificing electrical performance. Quality manufacturers employ precision winding techniques and rigorous testing protocols to ensure each smd high current power inductor meets strict specifications for inductance tolerance, current rating, and thermal characteristics. These components play crucial roles in switch-mode power supplies, DC-DC converters, motor drives, and renewable energy systems where high efficiency and reliability are paramount.