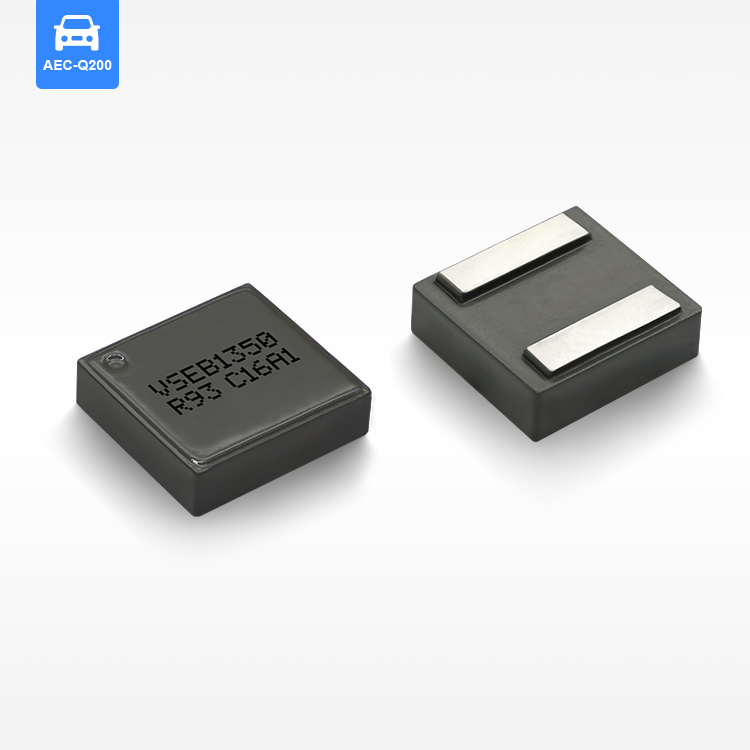

high current inductor

High current inductors represent a specialized category of passive electronic components designed to handle substantial electrical currents while maintaining optimal performance characteristics. These robust components serve as essential elements in power management systems, energy storage applications, and filtering circuits where conventional inductors would fail under high amperage conditions. The primary function of a high current inductor involves storing electrical energy in its magnetic field when current flows through its windings, then releasing this energy back into the circuit as needed. This energy storage and release capability makes high current inductors indispensable for voltage regulation, current smoothing, and electromagnetic interference suppression in demanding electrical environments. Technologically, these inductors feature enhanced construction methods including specialized core materials, optimized winding techniques, and superior thermal management systems. The core materials often consist of ferrite compounds, powdered iron, or advanced magnetic alloys that provide high permeability while minimizing core losses at elevated current levels. Wire gauge selection becomes critical, with manufacturers employing thicker conductors or multiple parallel windings to reduce resistance and prevent overheating. Advanced cooling mechanisms, including heat sinks and thermal interface materials, ensure reliable operation under continuous high current conditions. Applications for high current inductors span numerous industries and technologies. Power supply units rely on these components for output filtering and voltage conversion efficiency. Automotive electronics utilize them in electric vehicle charging systems, hybrid powertrains, and advanced driver assistance systems. Industrial automation equipment depends on high current inductors for motor drive circuits, welding equipment, and renewable energy systems. Telecommunications infrastructure employs these components in base station power amplifiers and signal processing units. The aerospace industry integrates high current inductors into satellite power systems and avionics equipment where reliability under extreme conditions remains paramount.