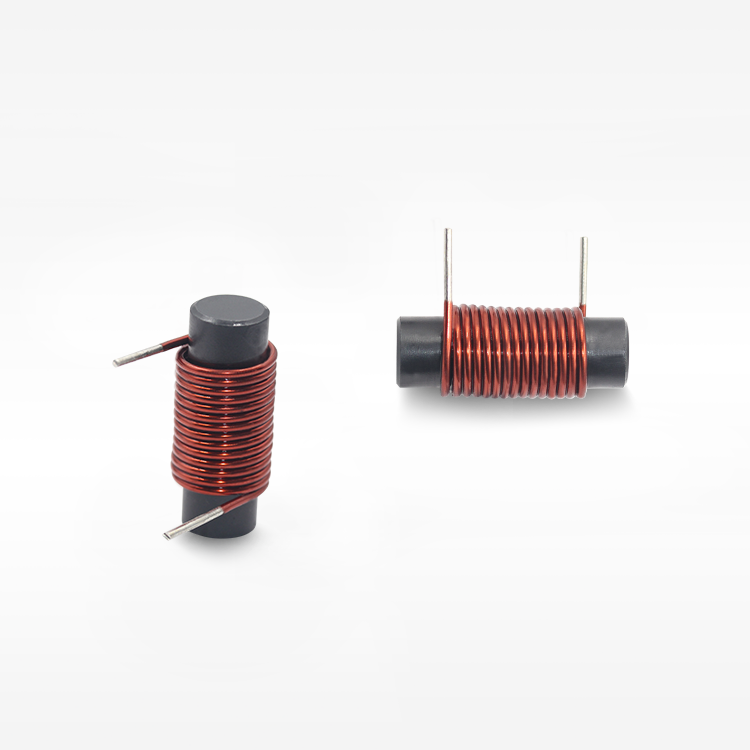

shielded power inductor supplier

A shielded power inductor supplier serves as a critical partner in the electronics manufacturing ecosystem, providing specialized magnetic components designed to manage electrical energy efficiently while minimizing electromagnetic interference. These suppliers focus on manufacturing inductors that feature magnetic shielding materials, typically ferrite cores or metallic shields, which contain the magnetic field within the component structure. The primary function of these components involves storing electrical energy in magnetic fields and releasing it when needed, making them essential for power conversion circuits, DC-DC converters, and switching power supplies. The technological features of products from a reputable shielded power inductor supplier include high current handling capabilities, low DC resistance, excellent thermal performance, and superior magnetic shielding effectiveness. These components operate by creating controlled magnetic fields that remain contained within the inductor housing, preventing interference with nearby sensitive circuits and components. Modern shielded power inductors incorporate advanced core materials such as powdered iron, ferrite, or specialized alloy compositions that optimize magnetic permeability while maintaining stability across varying temperatures and frequencies. The applications for these components span numerous industries including automotive electronics, telecommunications infrastructure, renewable energy systems, industrial automation equipment, and consumer electronics. In automotive applications, shielded power inductors are crucial for electric vehicle charging systems, engine control modules, and advanced driver assistance systems where electromagnetic compatibility is paramount. Telecommunications equipment relies on these components for base station power supplies, network infrastructure, and mobile device charging circuits. The shielded power inductor supplier typically offers customization services to meet specific electrical parameters, physical dimensions, and environmental requirements. Quality suppliers maintain rigorous testing protocols including magnetic field mapping, thermal cycling, vibration resistance, and long-term reliability assessments to ensure their products meet demanding application requirements across diverse operating conditions.