طراحی کابین مربوط به راحتی، ایمنی و تجربه رانندگی و سوار شدن در یک خودرو است. کابینهای هوشمند با ادغام فناوریهای مختلف فناوری اطلاعات و هوش مصنوعی، یک پلتفرم دیجیتال یکپارچه درون خودرو ایجاد میکنند که تجربه هوشمندی را برای رانندگان فراهم کرده و ایمنی رانندگی را افزایش میدهد. بهروزرسانی مداوم سیستمهای کابین هوشمند به حمایت مؤلفههای غیرفعال متکی است. سیمپیچها نقش مهمی در کابینهای هوشمند ایفا میکنند و عمدتاً برای ذخیره انرژی، فیلتر کردن، سرکوب نویز و هموارسازی جریان به کار میروند. انتخاب سیمپیچهای صنعتی خودرویی با قابلیت اطمینان بالا به بهبود کارایی و هوشمندی بیشتر کابین خودرو کمک خواهد کرد.

1- کاربردها سیمپیچهای صنعتی خودرویی در کابین

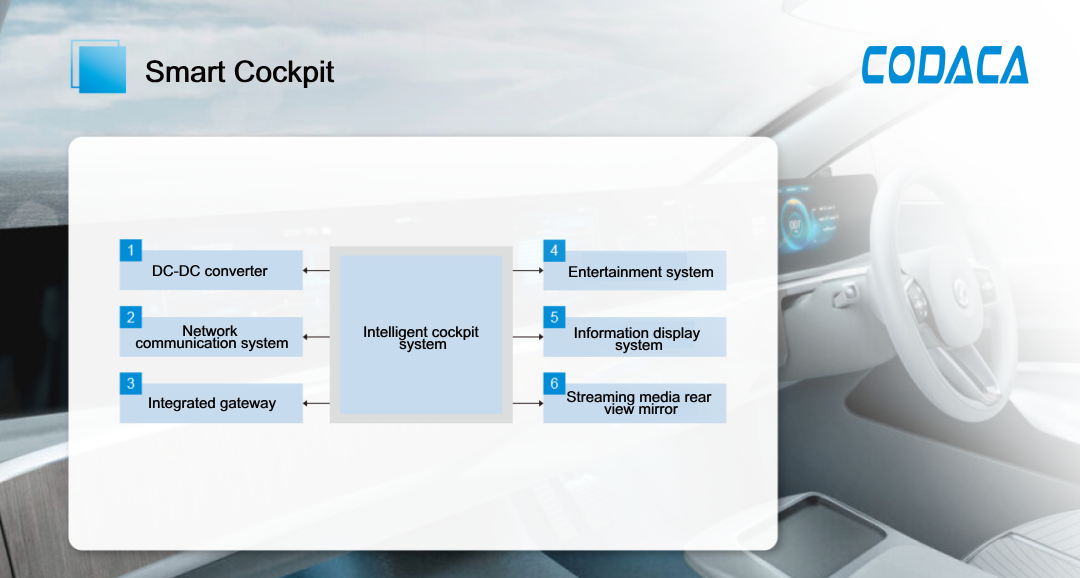

سیمپیچها در تقریباً هر ماژول از کابین هوشمند ادغام شدهاند، از جمله سیستم سرگرمی و اطلاعات (تقویتکننده خودرو)، نمایش اطلاعات رانندگی (تابلوی سازمانی/منبع تغذیه HUD)، تعامل انسان و ماشین (گفتگوی صوتی، ناوبری)، درک و کنترل هوشمند رانندگی (نظارت داخل خودرو، کولر هوا صندلی و سایر محرکههای موتوری)، ارتباطات شبکه، کنترلکننده دامنه کابین و غیره.

بر اساس آمارهای مربوطه، تعداد سیمپیچهای مورد استفاده در هر خودروی کابین هوشمند پیشرفته تا سال ۲۰۲۵ به ۱۵۰ تا ۱۸۰ عدد خواهد رسید که از این تعداد، ۵۰٪ برای مدیریت توان و ۳۰٪ برای سیستمهای ارتباطی استفاده میشوند. دامنه دمایی عملکرد بالا، عملکرد عالی در برابر لرزش و قابلیت اطمینان بالا (مطابق با استانداردهای AEC-Q200) اکنون به الزامات استاندارد برای سیمپیچهای خودرویی تبدیل شدهاند. سناریوهای کاربردی خاص و نیازمندیهای سیمپیچ به شرح زیر است.

1.1 سیستمهای اطلاعاتی و سرگرمی

در منبع تغذیه بوست DC-DC آمپلیفایر ماشین، مبدل DC-DC از سیمپیچهای توان با جریان بالا و سیمپیچهای قالبگیریشده استفاده میکند تا عملکرد پایدار در شرایط کاری مداوم با جریان بالا را تضمین کند. همچنین، از سیمپیچهای با DCR پایین برای کاهش تلفات مسی استفاده میشود. در مدار فیلتر آمپلیفایر صوتی، از سیمپیچهای کلاس D برای سرکوب نویز صوتی ناشی از ریپل منبع تغذیه استفاده میشود.

1.2 سیستمهای نمایش اطلاعات

سیستم نمایش اطلاعات هوشمند کابین خلبان شامل یک نمایشگر کنترل مرکزی بزرگ، یک صفحه کیلومترشمار LCD کامل، HUD و غیره است که عموماً از سلفهای قالبگیری شده و سلفهای فرکانس بالا (فرکانس کاری ۲ مگاهرتز) استفاده میکند. در میان آنها، سلف قالبگیری شده دارای چگالی توان بالا، راندمان بالا و غیره است که الزامات جریان پایدار دستگاههای نمایشگر را برآورده میکند. سلفهای فرکانس بالا برای رابطهای پرسرعت درون خودرو (مانند اترنت، USB و غیره) استفاده میشوند و هنگام افزایش نرخ انتقال، نویز فرکانس بالا را سرکوب میکنند و کیفیت سیگنال را تضمین میکنند. رابط گذرگاه CAN از چوکهای حالت مشترک برای جلوگیری از تداخل دادههای ابزار توسط موتورها و ایجاد سوسو زدن صفحه استفاده میکند.

1.3 سیستم تعامل انسان و ماشین

اندازه کوچک سیمپیچهای توان معمولاً در مدارهای حسگر لمسی و تشخیص بیومتریک استفاده میشود؛ فیلتر توان برای کاهش نویز کنترل صوتی (مانند آرایههای میکروفن) از حلقههای فریت برای فیلتر کردن نویز فرکانس بالا ناشی از شارژرهای داخل خودرو استفاده میکند.

1.4 سیستم ارتباطات شبکه

در خطوط انتقال داده نظارتی خودرو، از ترکیب سیمپیچهای فرکانس بالا و ماژولهای PoC برای تأمین جریان مستقیم و انتقال سیگنال تصویر روی یک سیم استفاده میشود. محصولات سیمپیچ نیازمند فرکانس عملیاتی گسترده و مشخصه امپدانس بالا هستند. در رابطهای ارتباطی اترنت گیگابیتی، معمولاً از سیمپیچهای حالت عمومی برای سرکوب نویز حالت عمومی سیگنالهای دیفرانسیلی استفاده میشود.

1.5 کنترلکننده حوزه کابین

کنترلکننده حوزه کابین، «مغز» سیستم سرگرمی اطلاعاتی خودرو، صفحه دیجیتال، HUD، کنترل کنترل هوا و حتی برخی از عملکردهای ADAS است که نیازمند تأمین برقی پایدار و تمیز میباشند. نقش اصلی القاگرهای در کنترلکننده حوزه کابین، ذخیره انرژی و فیلتر در مبدلهای DC-DC است.

1.6 آینه دوربینی پشتبینی جریانی

آینههای پشتبینی جریانی عمدتاً با استفاده از دوربینهای با کیفیت بالا در قسمت خارجی خودرو، شرایط جاده پشت خودرو را بهصورت زنده ضبط کرده و تصاویر را روی یک صفحه نمایش به جای آینههای سنتی نشان میدهند. به عنوان یک مؤلفه اساسی در سیستمهای مدیریت توان و طراحی سازگاری الکترومغناطیسی، القاگرها به طور گسترده در مدارهای آینه پشتبینی جریانی نیز استفاده میشوند.

نقشه شماتیک کاربرد کابین هوشمند خودرو

2- الزامات عملکردی القاگرها در کابینهای هوشمند

کابین هوشمند، به عنوان ماژول اصلی الکترونیک خودرو، نیازمند الزامات بسیار سختگیرانهای در مورد سیمپیچها است و باید تأمین برق پایدار، سیگنالهای خالص و تبدیل انرژی کارآمد را در محیطهای پیچیده تضمین کند. با ترکیب استانداردهای فنی صنعت و رویههای محصول، الزامات اصلی عملکردی برای سیمپیچها به شرح زیر است:

2.1 سازگاری با محیط و قابلیت اطمینان بالا

قابلیت کار در دامنه دمایی گسترده: پشتیبانی از دمای کاری بین -55 ℃ تا +150 ℃ یا بالاتر (در برخی کاربردها در محفظه موتور تا +170 ℃ نیز میرسد)، به منظور تطبیق با عملکرد مداوم ماژولهای الکترونیکی کابین (مانند صفحه کنترل مرکزی، کنترلکننده ADAS) در محیطهای سرد یا داغ شدید.

2.2 کارایی بالا و تلفات کم

انتخاب سیمپیچهایی با DCR پایین میتواند تلفات مستقیم در سیمپیچ را کاهش دهد، منجر به تلفات توان پایینتر و بازده تبدیل بالاتر شود و بهطور مؤثری سرعت پاسخگویی کابین هوشمند را بهبود بخشد. سیمپیچهای خودرویی قالبگیریشده CODACA از طریق نوآوری در مواد و فرآیند، DCR را تا ۳۰٪ کاهش داده و بازده توان را به بیش از ۹۸٪ افزایش دادهاند.

۲.۳ جریان اشباع بالا و ویژگیهای اشباع نرم

سیمپیچ باید بتواند جریانهای پیک گذرا را بدون اشباع شدن پشتیبانی کند تا اطمینان حاصل شود که تراشه SoC در هنگام افزایش ناگهانی قدرت پردازش، دچار فروپاشی ولتاژ نشود. برخی از سیمپیچهای خودرویی با جریان بالای CODACA از مواد هستهای مغناطیسی پودری آلیاژی استفاده میکنند که داخلی توسعه یافتهاند و دارای ویژگیهای عالی اشباع نرم هستند و حداکثر جریان اشباع آنها تا ۴۲۲ آمپر میرسد.

۲.۴ فرکانس بالا و سرکوب نویز

با پذیرش گسترده دستگاههای SiC و GaN، فرکانس منبع تغذیه مورد استفاده در کابینهای هوشمند باید از 2 مگاهرتز بیشتر پشتیبانی کند و نیاز به سیمپیچهایی با تلفات هستهای کم و فرکانس تشدید خودی بالا دارد تا کاهش بازده ناشی از کلیدزنی با فرکانس بالا جلوگیری شود. از نظر سرکوب نویز، سیمپیچهای قالبگرفته کاملاً محافظتشده میتوانند نویز فرکانس بالا را بهطور مؤثر کاهش دهند، در حالی که القاهای حالت مشترک (common-mode chokes) در کابین خودروها برای سرکوب تداخل نویز حالت مشترک روی خطوط توان و سیگنال استفاده میشوند.

2.5 کوچکسازی و یکپارچهسازی بالا

برای تطبیق با چیدمان با تراکم بالا در سیستمهای الکترونیکی کابین خودرو، سیمپیچها باید طراحی کوچک و فشرده داشته باشند. سیمپیچهای قالبگرفته درجه خودرویی CODACA دارای حداقل اندازه 4 میلیمتر × 4 میلیمتر × 2 میلیمتر هستند و با نوآوری در فرآیند و مواد، نیازهای مربوط به ابعاد کوچک، جریان بالا و تراکم توان بالا را برآورده میکنند.

2.6 آزمونهای قابلیت اطمینان محصولات خودرویی AEC-Q200

سرنشینهای مورد استفاده در کابینهای هوشمند باید آزمونهای قابلیت اطمینان محصولات خودرویی AEC-Q200 را پشت سر بگذارند تا عملکرد قابل اعتماد و پایدار الکترونیک خودرو در شرایط پیچیده تضمین شود. آزمونهای قابلیت اطمینان برای سرنشینها عمدتاً شامل بیش از ده مورد از جمله چرخه دما، نگهداری در دمای بالا، آزمون رطوبت بالا، آزمون لرزش و ضربه مکانیکی، آزمون لحیمکاری و غیره میشود. آزمایشگاه CNAS شرکت CODACA میتواند بهصورت مستقل آزمونهای AEC-Q200 را مطابق با نیازهای مشتری انجام دهد و گزارش آزمون را ارائه کند.

3- CODACA راهحلهای یکپارچه و با قابلیت اطمینان بالا از نوع سرنشین صنعتی برای کابینهای هوشمند ارائه میدهد

کوداکا بیش از 24 سال است که به تحقیق و توسعه در زمینه سیمپیچها اختصاص داده و بهصورت مستقل چندین سری از محصولات از جمله سیمپیچهای قالبگیریشده رده خودرویی، سیمپیچهای توان باجریان بالا رده خودرویی، سیمپیچهای رده خودرویی برای تقویتکنندههای دیجیتال و همچنین القاگرهای حالت مشترک رده خودرویی توسعه داده است. این شرکت راهحل جامع یکپارچهای از القاگرهای رده خودرویی با دستهبندیهای متنوع و قابلیت اطمینان بالا ارائه میدهد که نیازهای الکترونیک خودرو را برآورده میکند و به کوچکسازی، کاهش تلفات و افزایش بازده القاگرها در فضای کابین خودرو پاسخ میدهد و در دستیابی به توسعه کارآمد و هوشمند سیستمهای کابین هوشمند خودرو کمک میکند.

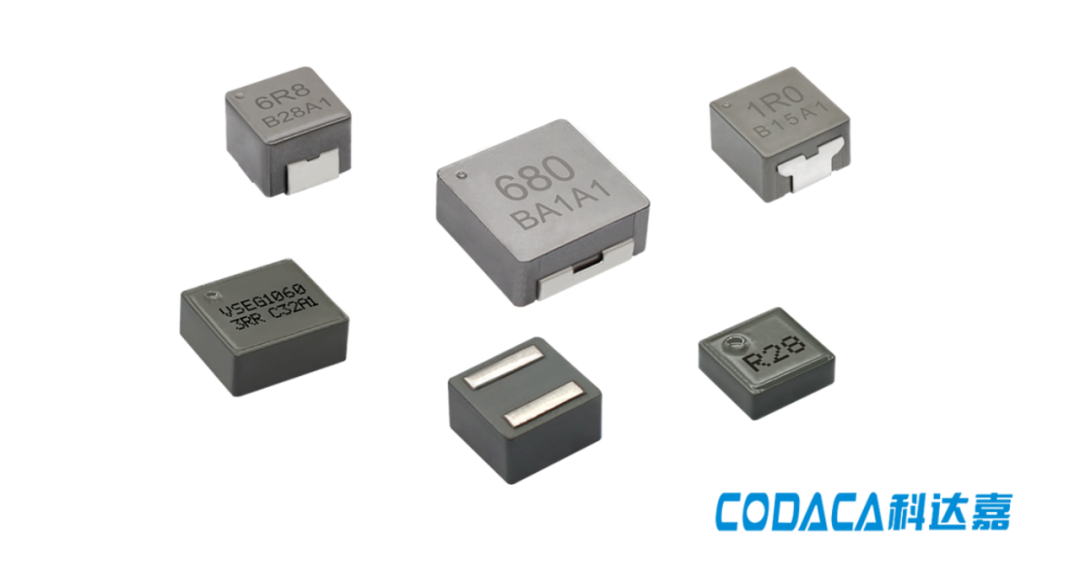

3.1 سیمپیچ توان باجریان بالا رده خودرویی

در سیستمهای کابین هوشمند، سیمپیچهای توان با جریان بالا عمدتاً در مبدلهای DC-DC ماژولهای مدیریت توان و مدارهای فیلتر استفاده میشوند. سیمپیچهای توان خودرویی CODACA دارای تلفات کم و جریان اشباع بالا هستند که حداکثر جریان اشباع آن به 422 آمپر میرسد و دامنه دمای کاری آن از -55 ℃ تا +170 ℃ است و برای محیطهای الکترونیکی پیچیده خودرو مناسب است.

3.2 سیمپیچ خودرویی برای تقویتکننده دیجیتال

سیمپیچها در تقویتکنندههای دیجیتال عمدتاً برای فیلتر کردن خروجی صوتی در کابین خودرو استفاده میشوند. به منظور برآوردن الزامات طراحی تقویتکنندههای خودرویی از نظر ابعاد کوچک، توان بالا، اعوجاج کم و قابلیت اطمینان بالا، CODACA به طور مستقل چندین سری از سیمپیچهای توان دیجیتال خودرویی توسعه داده است تا بازده تبدیل بالاتری و توان خروجی بیشتری داشته باشند و عملکرد صوتی با وفاداری بالا را تضمین کنند.

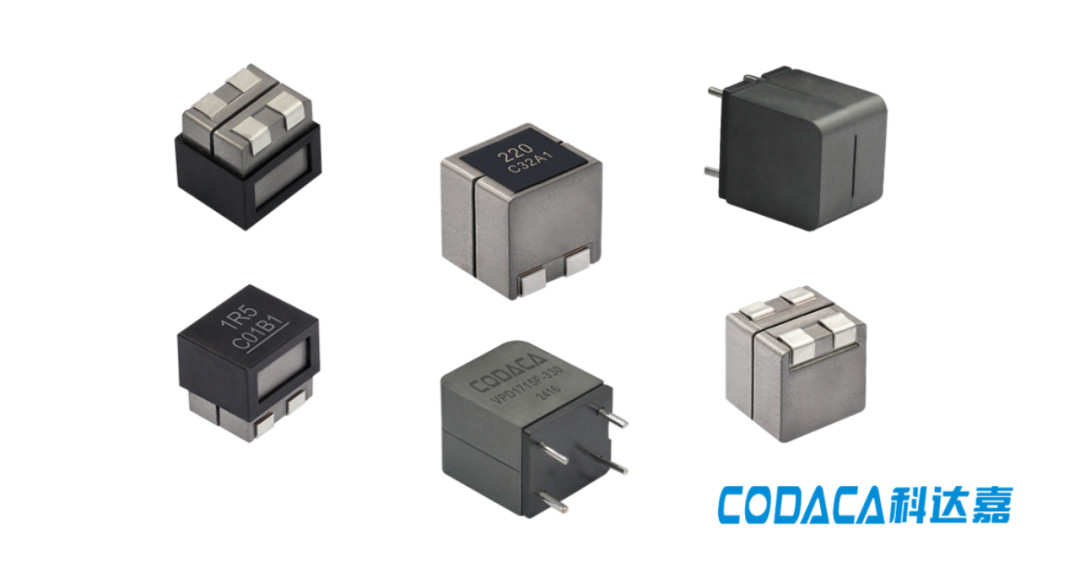

3.3 سیمپیچ قالبگیری شده خودرویی

سیمپیچ تزریقی درجه خودرویی CODACA از مواد هسته مغناطیسی کمتلفات و فناوری نوین الکترود برای رفع چالشهای فنی مانند پیچش سیمپیچ و ترکخوردگی محصول در حین فرآیند قالبگیری سیمپیچ استفاده میکند. این سیمپیچ تلفات کلی سیمپیچ را بیش از ۳۰٪ کاهش میدهد، در دمای بالا تا ۱۷۰°C کار میکند و بازده توان تا ۹۸٪ دارد که بهطور مؤثر قابلیت اطمینان سیستمهای کاکپیت خودرو و بازده تبدیل DC-DC را افزایش میدهد.

۳٫۴ اجزای EMI

سیمپیچهای حالت عمومی و مهرههای مغناطیسی بهطور گسترده در سیستمهای ارتباطی و مدارهای فیلتر قدرت کاکپیت خودرو برای سرکوب تداخل نویز بین خطوط سیگنال و خطوط برق استفاده میشوند. CODACA طیفی از اجزای EMI برای کاکپیت خودرو ارائه میدهد که شامل سیمپیچهای حالت عمومی و مهرههای مغناطیسی درجه خودرویی میشود.

اگر نیاز به مشاهده کاتالوگ محصولات الکترونیکی خودرو دارید، لطفاً با فروش تماس بگیرید یا ایمیلی برای ما ارسال کنید.