Automotive electronics live in a world of vibration, heat, moisture and voltage spikes—conditions far tougher than any smartphone or factory floor ever sees. To keep circuits safe and reliable, the industry turns to AEC-Q200, the global stress-test standard for passive components.

1- What AEC-Q200 Is

AEC-Q200 is the Automotive Electronics Council’s qualification specification for passive components such as capacitors, resistors, inductors, transformers, crystals and fuses. Compliance proves that a device can survive—and keep performing—inside a vehicle for its entire life.

Automotive-Grade Inductors Compliant with AEC-Q200 Standard

2- Latest Version: Rev. E, March 2023

Revision E widens the scope from 14 to 16 product categories, adding niobium capacitors, supercapacitors, fuses and trimmer potentiometers.

3- Test Menu for Magnetic Devices (Inductors / Transformers)

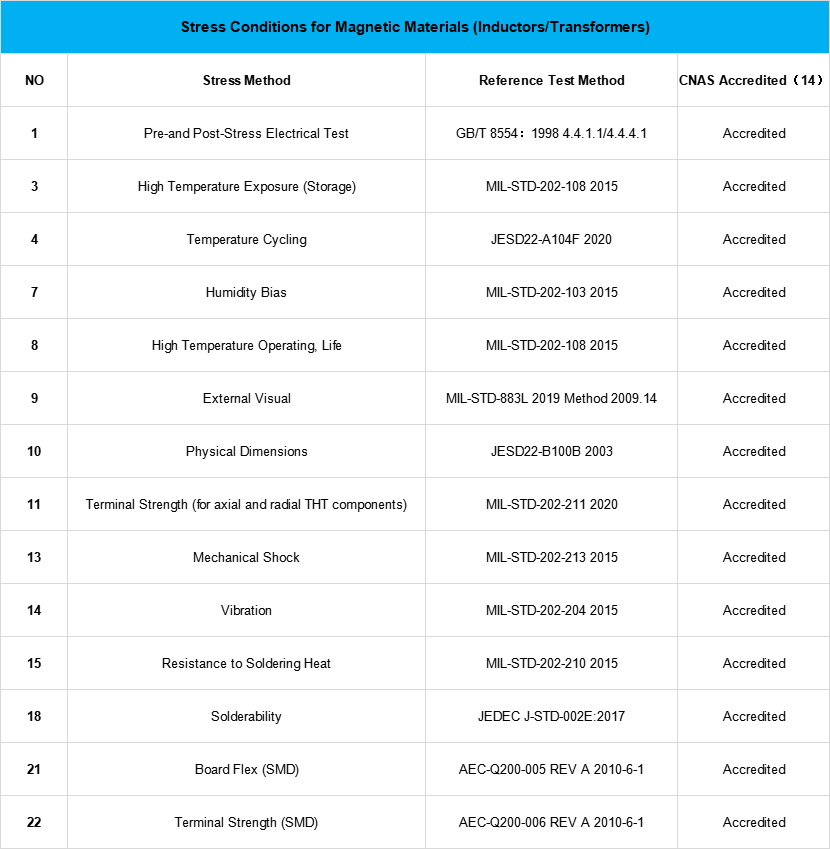

Table 5 of AEC-Q200 lists 18 required or conditional tests for magnetic devices:

(1)Pre- and Post-Stress Electrical Test

(2)High Temperature Exposure (Storage)

(3)Temperature Cycling

(4)Humidity Bias

(5)High Temperature Operating Life

(6)External Visual

(7)Physical Dimensions

(8)Terminal Strength (for axial and radial THT components)

(9)Resistance to Solvents

(10)Mechanical Shock

(11)Vibration

(12)Resistance to Soldering Heat

(13)ESD

(14)Solderability

(15)Electrical Characterization

(16)Flammability

(17)Board Flex (SMD)

(18)Terminal Strength (SMD)

Table 1: CODACA CNAS Laboratory Accredited AEC-Q200 Table 5 Test Items

4- Why OEMs and Tier-1s Demand AEC-Q200

Using AEC-Q200 qualified parts lowers design risk, speeds qualification cycles and supports functional safety analyses such as ISO 26262.

5- Common Misconceptions

5.1 “Industrial-Grade Is Close Enough”

Industrial parts often skip the 1,000-hour high-temperature tests or vibration profiles required by AEC-Q200. Substituting them can introduce latent failures in the field.

5.2 “Partial Testing = Full Compliance”

Because every test costs money and time, some suppliers pass only a handful of items and still claim “AEC-Q200 tested.” Always request the full test summary or third-party report.

5.3 “Certificate Equals Production Lot”

AEC-Q200 qualification is family-based; ongoing process control and lot acceptance testing are still essential. Verify that the supplier runs IATF16949 lines and keeps records for traceability.

6- How to Vet a Supplier

• Check scope of CNAS or A2LA accreditation for AEC-Q200 tests.

• Ask for the latest Rev. E test summary—look for 14+ items on inductors.

• Tour the plant: confirm IATF16949 certification, automated lines and lot-tracking systems.

• Benchmark temperature grades: Grade 0 (-55 °C to +165 °C) is the toughest available.

7- CODACA Automotive-Grade Inductors – A Case Study

• 24 years of inductor R&D, IATF16949 factories, CNAS-accredited lab.

• 14 AEC-Q200 Table 5 tests accredited; covers all required reliability stresses for inductors.

• Grade 0 temperature options up to +165 °C for under-hood or LED-driver designs.

8- Conclusion

If a passive component is not AEC-Q200 qualified, it is not automotive-grade—period. Make AEC-Q200 compliance your first filter, then dig into test reports, factory audits and temperature grades before locking in a supplier.