The growing demand for automation in manufacturing and service industries is driving the rapid development of humanoid robots. With the increase in degrees of freedom (DOF) and the improvement of response speed to the environment, humanoid robots have become more sophisticated, allowing them to simulate human movements more realistically. Higher degrees of freedom mean that humanoid robots require more motor drives, and inductors play an important role in the motor control, power management, and signal processing systems of humanoid robots.

1- The main application of inductors in humanoid robots

Inductors are mainly used in humanoid robots in motor drive, power management and signal processing.

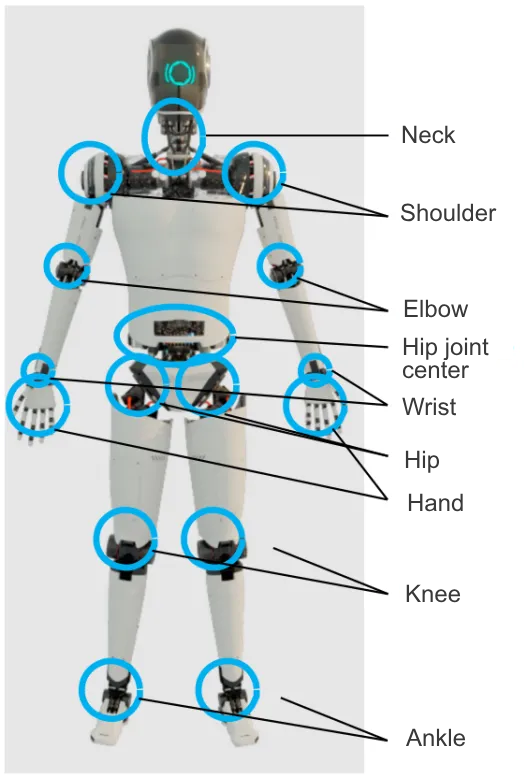

Motor drive: High-end humanoid robots on the market usually have 40-50 articulated motors, which determine the robot's freedom and flexibility. The inductor drives the motor to rotate smoothly through energy storage and smooth current, helping the humanoid robot motor control system to achieve joint movement, attitude adjustment and dynamic balance. Motor drives and high-power loads require inductors with high saturation current characteristics and high current carrying capacity to cope with instantaneous current fluctuations. At the same time, it is necessary to reduce losses to improve system efficiency and increase battery life.

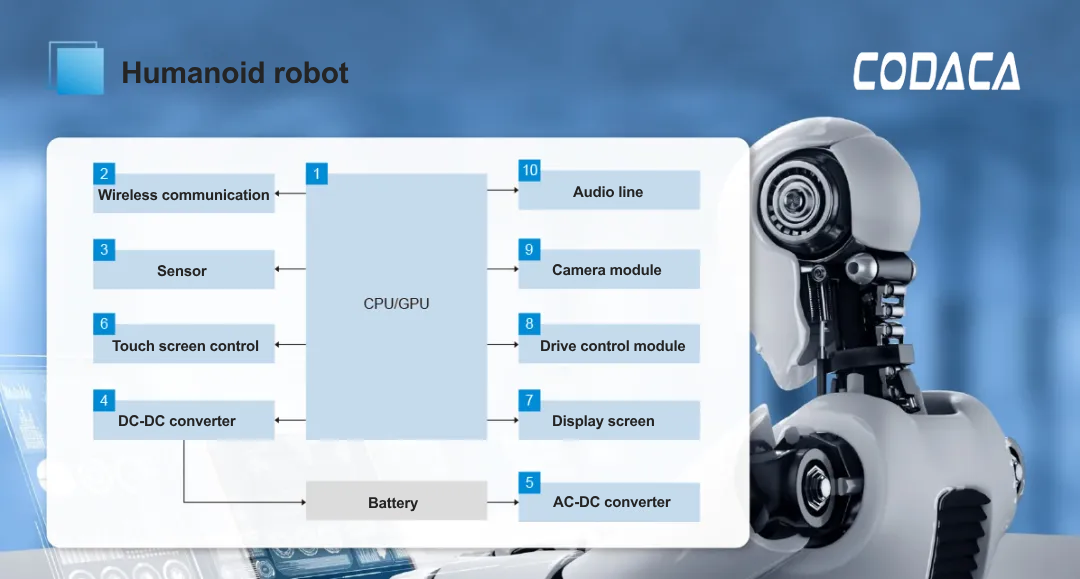

Power management: Inductors are the core components of DC-DC converters (such as buck and boost circuits) in power management systems, providing stable power supply at different voltages for AI processors, sensors, communication modules, etc., optimizing energy distribution and conversion efficiency. Low direct current resistance (DCR), high conversion efficiency to reduce power loss, high saturation current and good temperature stability are required.

Signal Processing: In signal processing systems, inductors are primarily used to suppress high-frequency noise and EMI, ensuring signal purity. For example, in the perception system, it helps realize the perception and interactive feedback of humanoid robots on the external environment. In communication and control systems, inductors use EMI design to ensure the anti-interference ability of radar, camera, wireless communication and other modules, and improve the operational stability of equipment.

Figure 1: The main location of the joint motor of the humanoid robot (image from TI)

2- The demand for inductors for humanoid robots

The electronic system of humanoid robots is complex, and to achieve precise motion control and reliable communication, it is inseparable from the support of basic components such as inductors. The technical characteristics of humanoid robots also determine their high requirements for the performance and structural design of inductor products. The requirements are mainly as follows:

2.1 Miniaturization and high power density

The internal space of humanoid robots is extremely compact, integrating a large number of motors, computing units (CPUs/GPUs), sensors, etc., and the power supply circuit board (such as POL, point-of-load converter) must be miniaturized. Inductors are required to be small and lightweight to fit compact structural designs, while also having high power density to achieve high power handling in a small footprint. Inductors with molded or shielded construction can withstand very large saturation currents and temperature rise currents in a small physical size, which is essential for achieving high power output in a limited space.

2.2 Strong anti-electromagnetic interference performance

The internal electromagnetic environment of robots is complex, with high-speed digital circuits, strong switching noise from motor drivers, and sensitive sensors (such as IMUs and cameras). The use of unshielded inductors will generate a strong magnetic field and become a source of electromagnetic interference, which will seriously affect the stability of the sensor readings and control system. The shielded inductor has minimal magnetic leakage, effectively reducing electromagnetic interference and ensuring the reliable operation of other components in the system. Therefore, molded inductors, high current power inductors and other power inductors with magnetic shielded structures are more ideal choices.

2.3 High saturation current

The dynamic load of the robot changes drastically, such as when starting suddenly, running, or lifting heavy objects, the current of the motor and computing unit will soar instantly. The inductor must be able to avoid magnetic saturation at high currents (i.e., the inductance value does not drop sharply), otherwise the power loop will get out of control, causing the system voltage to collapse and restart. Therefore, the inductance needs to have the characteristics of "soft saturation", that is, when approaching the saturation current, the inductance value decreases slowly, rather than falling off a cliff. This provides a buffer for the power control system and enhances the reliability of the system.

2.4 Strong anti-vibration and impact performance

Humanoid robots move frequently, have a lot of mechanical vibration, and the inductor needs to have vibration and shock resistance, its solder joints should be firm, and the shell and internal coil can withstand mechanical stress. The inductor of the molded structure completely solidifies the coil inside the magnetic material, which has extremely high mechanical strength and has very strong shock resistance, so it is widely used in humanoid robot systems.

2.5 Adapt to high-frequency and high-temperature environments

The inductor needs to have good high-frequency characteristics, which can effectively suppress high-frequency interference, reduce ripple and noise, and maintain low energy loss at high frequencies to improve conversion efficiency.

In addition, the inductor should be able to keep the inductance value stable in a high temperature environment, the Q value decreases small, and the performance is not easy to degrade, so as to ensure that the inductance performance of the robot is reliable in long-term work.

Fig.2 Application of inductor in humanoid robot

3- Codaca inductor solution for humanoid robots

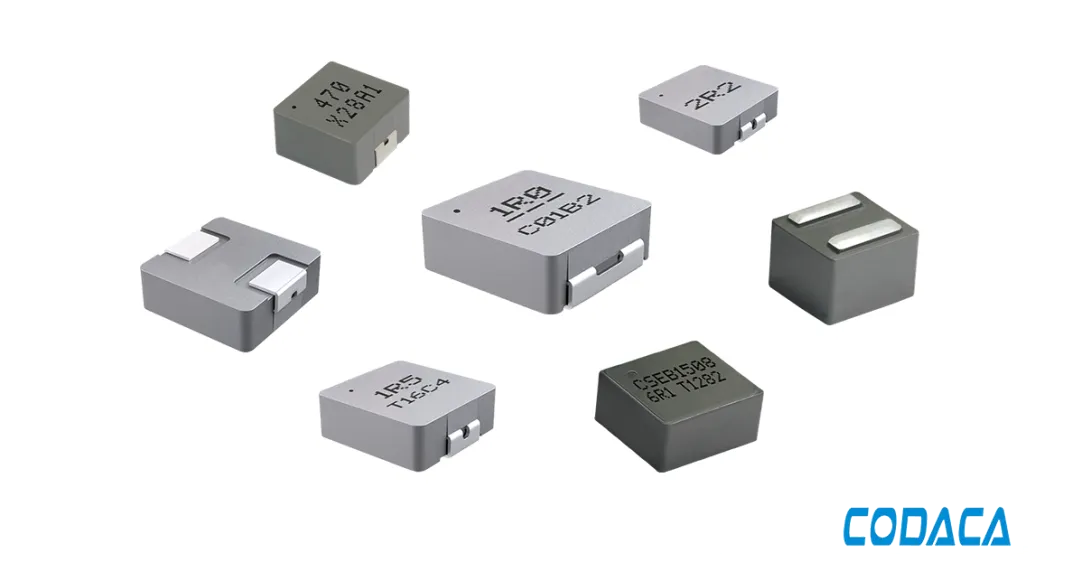

In applications such as humanoid robots, which combine high power density, high efficiency, high reliability, complex EMI environments, and harsh mechanical conditions, high-current, shielded, alloy powder core inductors have become the undisputed mainstream choice in power supply circuits, especially POL power supplies for core computing units and joint motor drives, due to their comprehensive performance advantages. Its design perfectly balances the three core challenges of performance, size, and reliability.

Through independent research and development and technological innovation, Codaca provides adaptive inductor solutions for humanoid robots, and the company has launched multiple categories and models of products such as magnetic shielded structure high current power inductors, thin and light molded inductors, and common mode chokes. It can provide different electrical characteristics to meet the high-performance requirements of inductors in different scenarios of humanoid robots, and is widely used in robot communication and navigation modules, power modules, motor drive modules, robot control boards and other modules.

3.1 Compact high current power inductor

Compact high current power inductors are mainly used in DC-DC modules in humanoid robot motor drive and power management systems. The high-current inductor adopts the low-loss metal magnetic powder core material independently developed by Codaca, which has the characteristics of high saturation current, low loss, high conversion efficiency, and high operating temperature to ensure the performance and endurance of humanoid robots. The high-current inductor can be up to 422A and the operating temperature can be up to 170°C. At the same time, the product adopts a magnetic shielded structure, which has strong anti-electromagnetic interference performance. It fully meets the needs of humanoid robots for high saturation current, high operating temperature and low electromagnetic interference.

Recommended models: CSBX, CSBA, CSCM, CSUT, CSCIL, etc.

3.2 Thin and light molded inductors

Molded inductors are mainly used in humanoid robot display modules, touch screen control modules, DC-DC modules, etc. The molding power chokes adopt the low-loss alloy powder independently developed by CODACA, which has low loss, high efficiency, wide application frequency, and can reduce the noise to ultra-low. It adopts a thin and light design (minimum size of 2mm), saves PCB space, is suitable for high-density mounting, and has strong resistance to mechanical shock and vibration (vibration resistance is more than 10G), meeting the needs of humanoid robots for high power density and high stability.

Recommended models: CSAG, CSAC, CSAB, CSEB, CSHB, etc.

3.3 SMD power inductor

Codaca SMD power inductors are mainly used in camera modules, audio modules, DC-DC modules, etc., which can meet the needs of small inductor size, large current, high conversion efficiency, etc.

Recommended models: SPRHS, CSUS, CRHSM, VCRHS, SPQ, etc.

As a leading supplier in the field of magnetic component technology, Codaca Electronics has been focusing on inductor development for 24 years, and engineers can match the appropriate inductance value, rated current, switching frequency, product size, etc. according to the specific performance requirements of each subsystem of humanoid robot for inductors. Please contact Codaca sales staff for more detailed information.