Introduction: While CODACA’s industrial and automotive inductors may appear similar externally, their core specifications, certifications, and performance diverge significantly. This analysis details key distinctions in naming conventions, quality systems, testing standards, performance benchmarks, and design choices to guide component selection for mission-critical applications.

1. Product Naming Conventions

1.1 Automotive-Grade Inductors:

◾ Designed for automotive electronics with stringent reliability demands.

◾ Model prefix: "V" (denoting Vehicle).

◾ Key Series: Molded Power Choke (VSAB, VSHB, VSHB-T, VSEB-H), High-Current Power Inductor (VSRU), Rod Inductor (VRKL0740).

1.2 Industrial-Grade Inductors:

◾ Target applications: Industrial power supplies, control systems, renewables, telecom.

◾ Identification Rule: All CODACA inductors not explicitly labeled as "Automotive-Grade" fall under this category.

2. Quality Management & Documentation

Automotive-grade components demand stricter controls across development, testing, manufacturing, and materials, requiring extensive documentation.

2.1 Industrial-Grade Documentation:

◾ Datasheet Approval Forms

◾ National Standard Reliability Test Reports (7 items)

◾ Compliance Docs: RoHS, REACH, Halogen-Free

◾ FMD/MSDS

2.2 Automotive-Grade Additional Requirements:

◾ APQP (Advanced Product Quality Planning)

◾ AEC-Q200 Compliance (Mandatory)

◾ Dedicated Production Lines

◾ IATF 16949 Certification

◾ VDA 6.3 Process Audits (German automotive)

◾ PPAP Submission (Level 3 offered)

◾ IMDS/CAMDS Material Reporting

◾ Critical Process Capability (CPK) ≥ 1.67

3. AEC-Q200 Testing: The Automotive Benchmark

3.1 Scope: Validates reliability under stress tests (electrical, mechanical shock, vibration, temp cycling, humidity, solderability).

3.2 CODACA Automotive Inductors:

◾ Certified to Grade 0 (highest level).

◾ Operating Temp: -55°C to +165°C (exceeds standard Grade 0).

3.3 CNAS Lab Capability: CODACA performs in-house AEC-Q200 testing.

3.4 Industrial-Grade with AEC-Q200: Select industrial series (e.g., some variants) pass testing at Grade 1 (-55°C to +155°C) for harsh environments.

◾ Note: This does not equate to automotive-grade status due to differences in systemic requirements, production controls, and documentation.

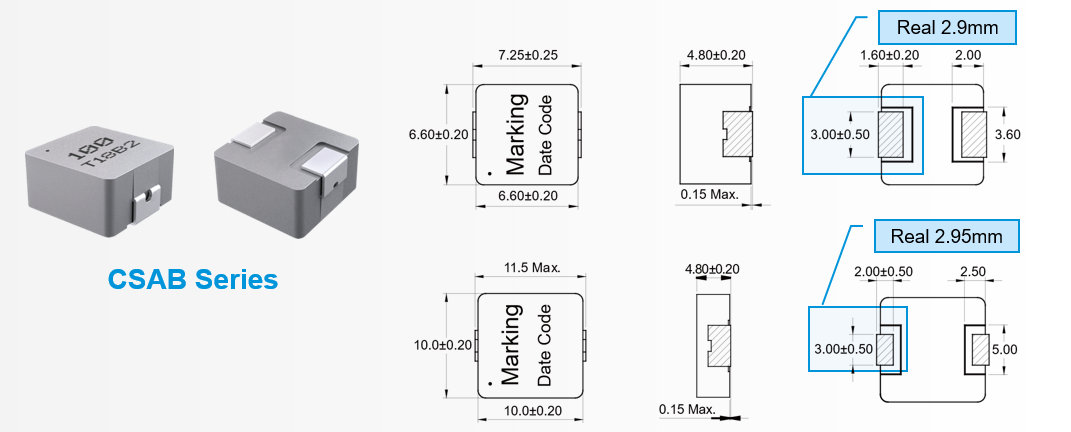

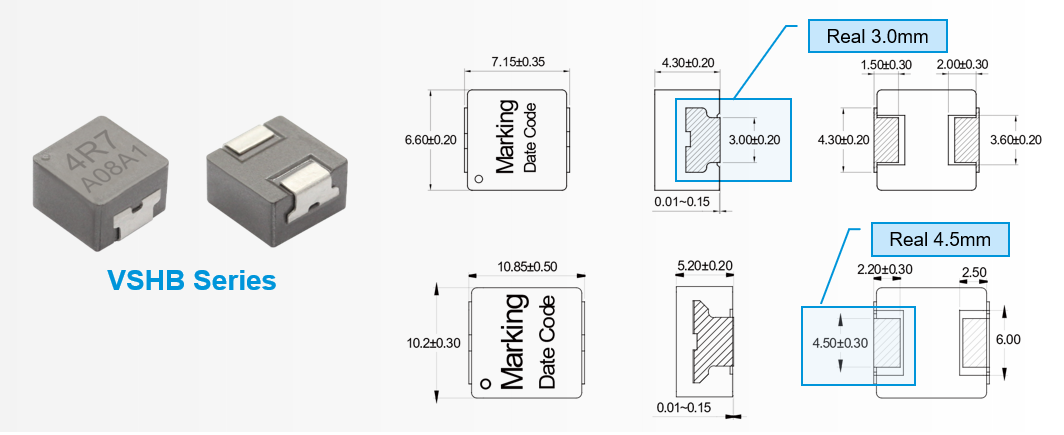

4. Performance Comparison: CSAB (Industrial) vs. VSHB (Automotive) Molded Inductors

| Feature | CSAB (Industrial) | VSHB (Automotive) | Automotive Advantage |

|---|---|---|---|

| Terminals | Narrow design | Wider design | ↑ Mechanical robustness |

| Vibration Resistance | ≥ 5G (meets basic AEC-Q200) | ≥ 10G | ↑ Vibration endurance |

| Core Material | Low-loss alloy powder | Low-loss alloy powder | — |

| Molding Process | Cold pressing | Low-pressure hot pressing |

↑ Core density & voltage withstand ↑ ↓ Coil deformation/cracking ↓ |

| DC Resistance (DCR)/Current | Standard design |

Higher permeability → Fewer turns/thicker wire → ↓ DCR / ↑ Rated current |

↑ Electrical efficiency |

| Max Frequency | 800 kHz | 1000 kHz | ↑ High-frequency suitability |

| Temp Range | -40°C to +125°C (AEC-Q200 Grade 1) | -55°C to +165°C (AEC-Q200 Grade 0) | ↑ Thermal resilience |

| Winding/Welding | Inner-outer winding; Laser weld (some) | Outer-outer winding; 100% Resistance weld | ↓ Short-circuit risk ↑ Reliability |

| Marking | Ink printing (may fade) | Laser engraving | ↑ Permanence & traceability |

5. Conclusion: Engineered for Extreme Reliability

5.1 Automotive-grade inductors demand unparalleled resilience against harsh operating environments (temperature extremes, vibration, longevity), necessitating:

◾ Robust quality management (IATF 16949, APQP, PPAP)

◾ Rigorous process controls (CPK ≥ 1.67, VDA 6.3)

◾ Superior component-level performance (AEC-Q200 Grade 0)

5.2 CODACA’s Core Capabilities:

◾ 24+ years of inductor design expertise

◾ IATF 16949 certified manufacturing

◾ CNAS-accredited in-house test lab (AEC-Q200 validation)

◾ APQP-driven development & strict supplier vetting

◾ Custom design solutions for industrial/automotive applications

◾ Industry-leading quality & reliability standards