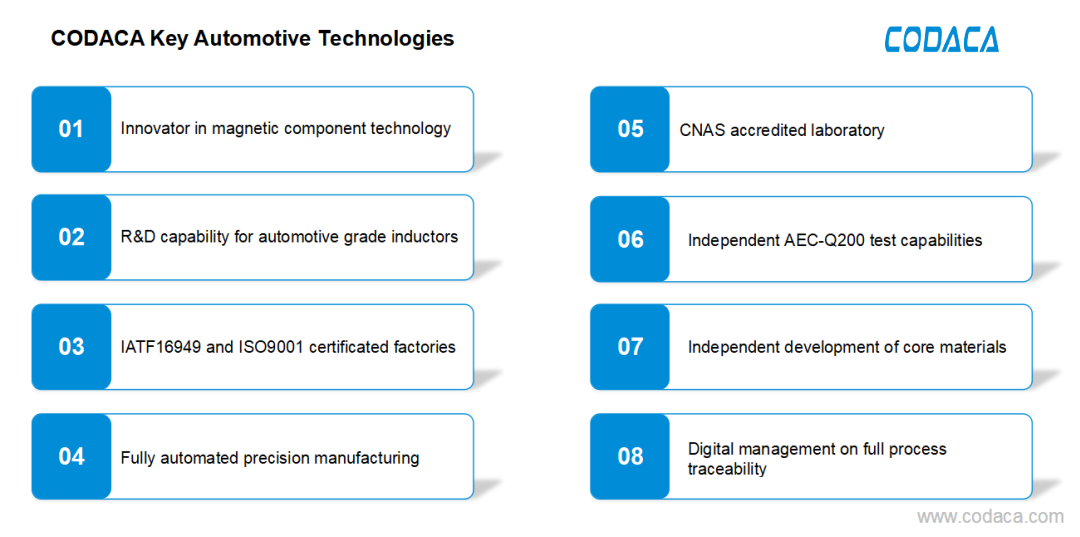

100% Self-Determined Manufacturing, CODACA’s High-Reliability Automotive-Grade Inductors Drive Innovation in Automotive Electronics

“With the growing functionality of new energy vehicles and intelligent connected cars, automotive components are trending toward integration—placing new demands on the electrical performance and size of power inductors. Moreover, to ensure safe and stable vehicle operation, low-loss, high-reliability, and high-quality automotive-grade inductors are indispensable.”

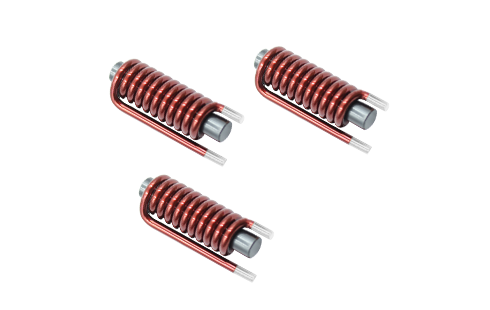

As a professional manufacturer of automotive-grade inductors, CODACA has specialized in high-power inductor development for 24 years. The company has independently developed multiple product lines, including automotive-grade molded inductors, high-current inductors, and rod inductors. Equipped with a CNAS-accredited laboratory, CODACA delivers premium automotive-grade inductors that fuel innovation in automotive electronics.

1.Technological Innovation: Elevating Automotive-Grade Inductor Performance

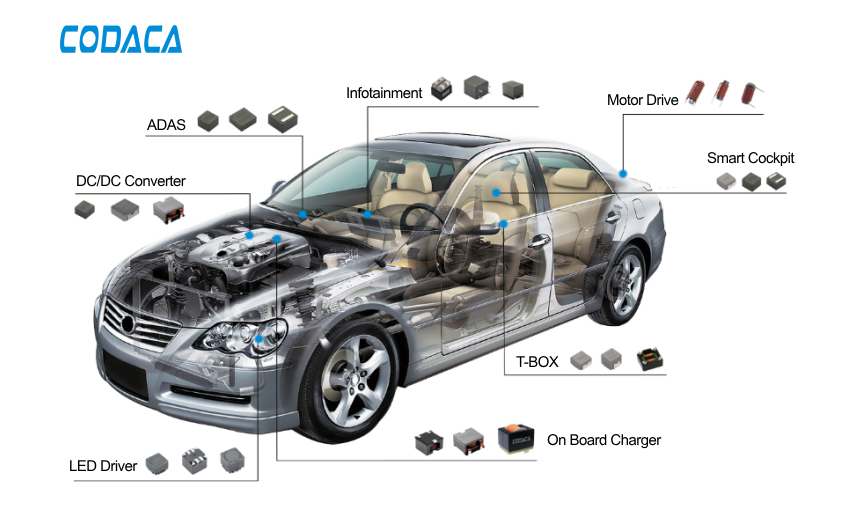

CODACA’s automotive-grade inductors are widely deployed in critical automotive systems, such as:

● Smart cockpits

● Advanced Driver Assistance Systems (ADAS)

● Central control units

● Headlamp driver modules

● In-vehicle entertainment and audio systems

● Battery Management Systems (BMS)

● T-BOX units

These inductors are engineered to deliver low loss, low DCR (direct current resistance), high temperature tolerance, and exceptional reliability—key traits for demanding automotive environments.

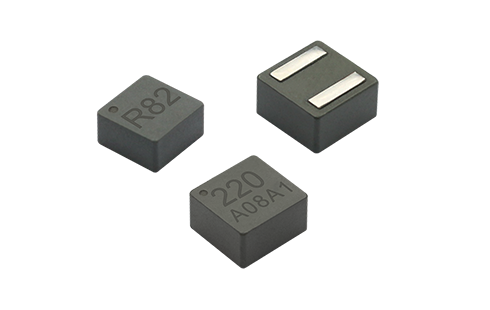

CODACA prioritizes R&D and technological breakthroughs, integrating innovative solutions into its automotive-grade molded inductors:

● Independently developed low-loss magnetic core materials

● Hot-press molding technology

● T-Core magnetic core designs

● External winding configurations

● Wide-terminal structures

These advancements significantly reduce inductor loss and address critical technical challenges, such as coil misalignment and product cracking during molding.

The results are tangible:

● Over 30% reduction in overall loss

● Operating temperature capability up to 165°C (exceeding AEC-Q200 Grade 0 standards)

● Power conversion efficiency as high as 98%

These improvements directly enhance product reliability and energy efficiency in automotive applications.

2. Full In-House Control: From Materials to Manufacturing

CODACA maintains 100% in-house control over its automotive-grade inductor production, ensuring quality and consistency at every stage:

● Certified Production: Manufacturing takes place in state-of-the-art facilities compliant with the IATF16949 automotive quality management system.

● In-House Materials: Core magnetic materials are independently developed, eliminating reliance on external suppliers for critical components.

● Rigorous Testing: A CNAS-accredited laboratory enables comprehensive reliability testing per AEC-Q200 standards, validating performance under extreme conditions.

● Customization Capability: Beyond standard products, CODACA rapidly develops tailored automotive-grade inductors to meet specific customer requirements.

3. Recommended Automotive-Grade Inductor Products

By combining technological innovation with full in-house control, CODACA’s automotive-grade inductors stand as a trusted choice for powering the next generation of automotive electronics—delivering the reliability, efficiency, and performance required for today’s intelligent and electric vehicles.